While the many of our customers like to take advantages of Roller Die + Forming’s Standard Tooling Library to help significantly cut the up-front cost of tooling, other customers have very specific and unique shapes they need. In these cases, custom metal forming is the best option for their parts as they can specify the […]

Industrial Manufacturing & Tooling Capabilities

High-quality tools are essential to achieve high-quality parts. Our Industrial Manufacturing & Tooling Capabilities at Roller Die + Forming include several decades of experience providing solutions to meet the requirements of respective clients from a wide range of industries. From design to roll forming, assembly, finishing, and production, our qualified experts at Roller Die + Forming can assist you with all your industrial manufacturing, custom roll forming, and related roll form tooling needs.

At Roller Die + Forming, our industrial manufacturing and tooling capabilities focus on creating solutions that are used in different applications in all major industries. From automotive parts to lock components, electronic parts, medical parts, packaging parts, and more, our tooling solutions are suitable for producing complex and even beautiful cosmetic components.

In addition, our experts use the most innovative, state-of-the-art tools, die, and forming equipment to create tooling solutions that guarantee quality and efficiency. We also offer in-house tooling services from wire EDM to 3D printing to model and create tooling. Our dedicated team of experienced design-build experts, engineers, and craftsmen make us stand apart from other roll forming companies. No matter your manufacturing and tooling needs, we have the ideal solution for you.

Roller Die + Forming Additional Services

Roll Forming Materials

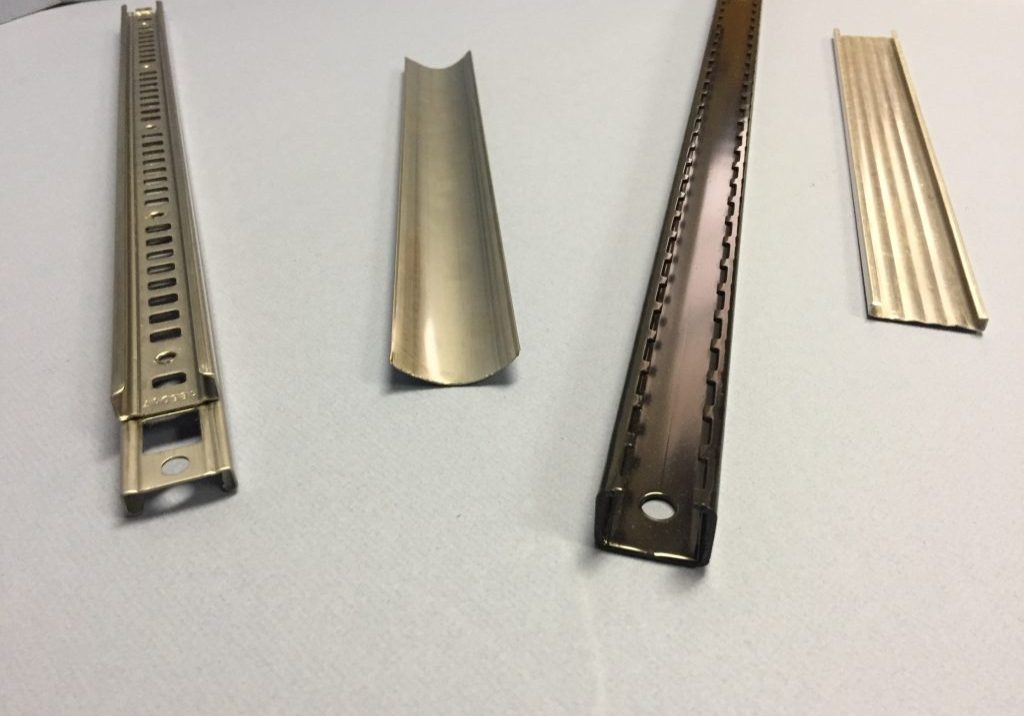

Almost any material that can tolerate bending to a desired radius can be roll formed. The more ductile the material is, the better it will roll form. The roll forming process can handle ferrous, nonferrous, hot rolled, cold rolled, polished, plated, or pre-painted metals producing excellent results.

Roller Die + Forming News & Articles

Manufacturing Trends in 2019

The economy in the U.S. is strong and, even with the uncertainty in manufacturing caused by the tariffs, roll forming is still going strong. The team at Roller Die + Forming pays attention to a broad variety of economic indicators to be able to make strategic growth and purchasing decisions. While the economy still cycles, […]

Moving from Extrusions to Roll Forming

Do you use fabricated aluminum extrusions? Many custom metal parts are made using extrusion that would be cheaper or easier to make using roll forming. Roller Die + Forming engineers can look at the particular part you’re making to determine whether you could save money or have a faster process using roll forming. You may […]

- « Previous

- 1

- …

- 4