Category: Roll Forming

Amortizing the Costs of Tooling

Amortizing the Costs of Tooling

When you are preparing to run a new roll formed part, one of the biggest costs is the upfront cost of tooling. While Roller Die + Forming’s Standard Tool Library

Read More

Reasons why Custom Powder Coating is Optimal for Metals!

Powder coating provides a tough finish that resists corrosion. Compared to traditional liquid finishing, it emits less hazardous materials – for a safer process. (more…)

Read More

Getting Your Roll Formed Parts Just in Time

Drowning in a sea of parts you don’t need yet? Expanding to meet the needs of a new order only want to increase production and not warehouse space?

If this sounds like you, you’re probably

Read More

Using Roller Die’s Standard Tolerance Guide

If you’re looking to purchase roll formed parts, one question you may have is about the tolerances we can hold. For certain applications, such as the in the appliance and automotive industries

Read More

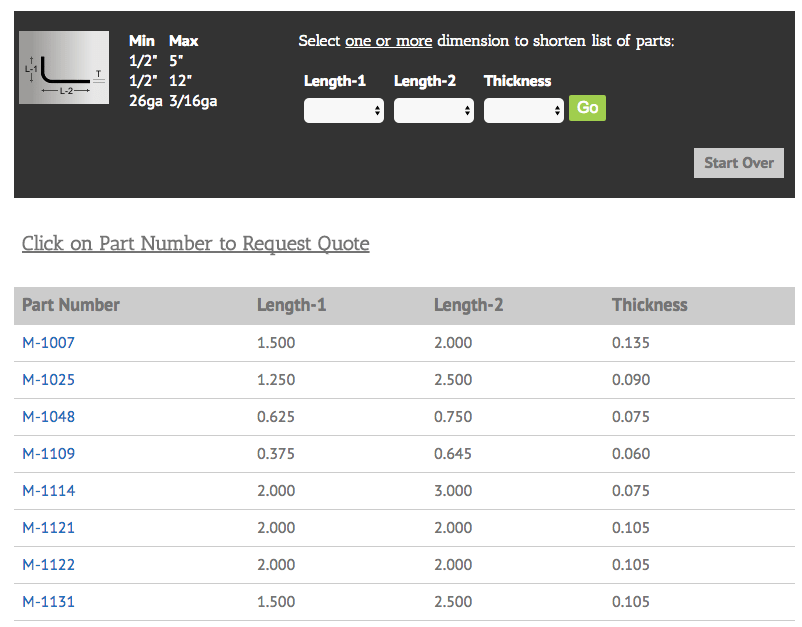

Working with the Standard Tooling Library

One of the frequent questions for our engineering group is how customers can economize on their tooling costs by using Roller Die + Forming’s standard tooling library. Using our standard tooling

Read More

Roll Formers: Best for Precision Results

Your business demands the strength and precision of a roll formed part. At Roller Die, a high-qualified roll former, our tools are engineered to form each shape to your required tolerance. No matter

Read More

Roll Forming Greenhouses

If you’re in the business of designing and making greenhouses, you are probably designing parts that are sturdy, lightweight, and cheap. You also want to design structural parts that you can use

Read More

Roll Forming for the Appliance Industry

Whether you’re producing thousands of dishwashers for commercial kitchens or beautiful refrigerators for modern homes, your manufacturing process probably involves roll formed parts. Using roll

Read More

Roll Forming and the Office Furniture Market: A Perfect Match

Some manufacturing processes and end products were simply made for each other. Roll forming metals and the contract office furniture share such a natural relationship. Contract office panel

Read More

Roller Die Runs .250 Grade 50 Steel

Roller Die runs 0.250 grade 50 steel. We just completed a very large order of .250 X 2.750 X 2.750 angle. This order ran off one of the tools that we have in our standard library of tooling. As

Read More

español

español English

English English

English español

español