Author: Roller Die + Forming

How Does Powder Coating Work?

At Roller Die + Forming, we offer a number of finish services to complement our metal forming process. Finishing services are available and useful for applications where the metal needs a coating to

Read More

Roller Die is Working Out in Sports Stadiums

Roller Die is Working Out in Sports Stadiums. Our facility in Louisville, Kentucky is currently producing bleacher seats for a football stadium. While we are always in the process of producing a wide

Read More

Roll Forming and the Office Furniture Market: A Perfect Match

Some manufacturing processes and end products were simply made for each other. Roll forming metals and the contract office furniture share such a natural relationship. Contract office panel

Read More

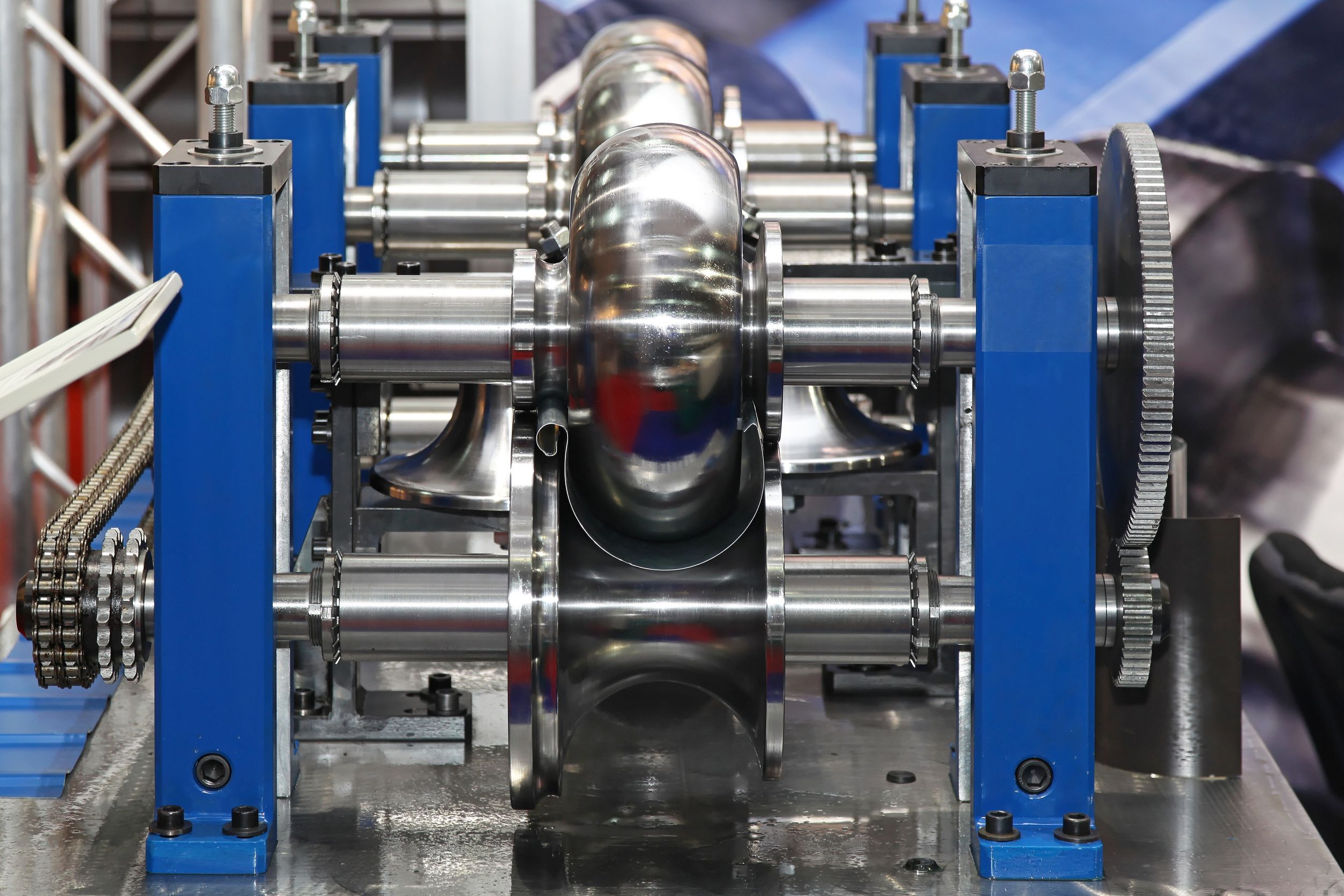

How does Roll Forming Work?

Roll forming is our passion here at Roller Die + Forming. Roll formed material is often the chosen process for shaping metal because it provides a great and accurate product for a reasonable price.

Read More

Excellence in Engineering at Roller Die + Forming

The engineering staff here at Roller Die + Forming boasts over 170 years of combined roll forming experience. We understand the art and magic that goes into making roll formed parts. Every day, we

Read More

Roll Forming: a Sustainable Manufacturing Process

“Sustainability” has grown to become an essential business strategy in manufacturing and is important to the team at Roller Die + Forming. Shareholders continually push manufacturers for

Read More

Roller Die Supports USA Cares

The team at Roller Die + Forming is choosing to support USA Cares again this year as part of our holiday philanthropy efforts. Many of our employees are veterans and we want show that we appreciate

Read More

Roll Formed Parts in the Truck Trailer Market

The Roll Forming process is particularly valuable when the customer’s volume increases exponentially over press brake. Usually, at this point, Roll Forming becomes more affordable for the volume of

Read More

Roller Die Runs .250 Grade 50 Steel

Roller Die runs 0.250 grade 50 steel. We just completed a very large order of .250 X 2.750 X 2.750 angle. This order ran off one of the tools that we have in our standard library of tooling. As

Read More

español

español English

English English

English español

español