At Roller Die + Forming, we offer Aluminum Extrusion services. Our team of experts can handle virtually all types of aluminum extrusion to your unique requirements. We use the best tools and processes to achieve accurate and highly durable parts, with no room for inconsistencies. From prototype to production, Roller Die + Forming remains your reliable partner for your various extrusion needs.

Aluminum Extrusion vs. Roll Forming

Challenge: A potential customer found the RDF website through an Internet search. After a review of our extensive capabilities, an inquiry was submitted for assistance with a complete conveyor system redesign.

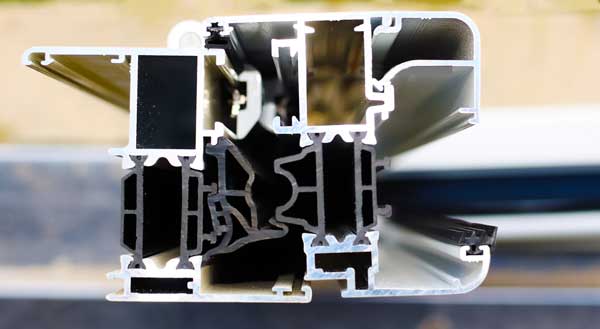

This customer wanted to convert a very costly aluminum extrusion system to a much more manufacturing friendly roll formed system, produced in a quarter-hard stainless steel. With the current supply chain for this system located in Europe, the customer focus was on a two-fold cost reduction initiative: roll formed shapes of the highest quality, produced in the US (roll forming shapes vs aluminum extrusion).

Solution: Through numerous conference calls and concept design sessions, we were able to develop a concept consisting of just a single roll formed shape.

This easily roll formed shape could be mirrored back-to-back, utilizing any two parts yielded at the production line. These two parts would then be spot welded together down the length of the part. This process essentially replicated the tightly toleranced aluminum extrusion design, but at a fraction of the price. Additionally, the strict quality standards Roller Die implemented and repeatability were maintained on critical parts where consistency is the key to success.

Result: The lower cost solution has since paved the way for a much more price-competitive system in the marketplace, and sales for this system have seen substantial growth over the past year. Currently, we are working with this customer on a new project of similar scope, and are continuing to build a solid, long-term customer relationship, while also still providing those win-win solutions.

Roller Die + Forming News & Articles

Roller Die Team has Deep Experience

Roll forming, as the engineers often say, is as much an art as a science. Knowing just how much to bend a part so that when it is through, it is exactly the shape required. Not only does our engineering team have extensive experience designing for roll forming, the rest of our staff does as […]

Roller Die + Forming

Roller Die + Forming has been in business for over 85 years delivering high quality roll formed parts to our customers. We have 5 manufacturing plants located in Louisville and Frankfurt, Kentucky, Rossville, Georgia, Green Cove Springs, Florida, and Queretaro, Mexico. Our top priority is to produce custom roll-formed products that exceed our customer’s […]

Secondary Operations, from Press Brake to Powder Coat

Roller Die offers a number of secondary services to help our customers receive the exact custom metal part for their process. While metal roll forming is our main service, we can do additional operations in-line, keeping costs low. From pre-punch to cut-off, our roll lines are equipped with the equipment to create a profile that […]

- « Previous

- 1

- …

- 4