Rapidly growing custom metal forming company Roller Die recently purchased the assets of Redall Industries, a roll forming facility located in Yale, Michigan. 12/30/24 – Roller Die + Forming recently completed an asset purchase from Redall Industries, located in Yale, Michigan. This existing roll form facility has a number of advanced manufacturing technologies and will […]

Roll Formed Cold Rolled Steel

Cold rolled steel is steel that has been rolled into the desired cross section at (or slightly above) room temperature. Since cold rolled steel forming is done when the steel is in a rigid state, more pressure is required, but there is no cooling period and no shrinking or warping during cooling. Cold rolled steel possesses a high tensile strength and a high degree of hardness and smoothness in the finished surface. These characteristics of cold rolled steel improve its ability to be machined.

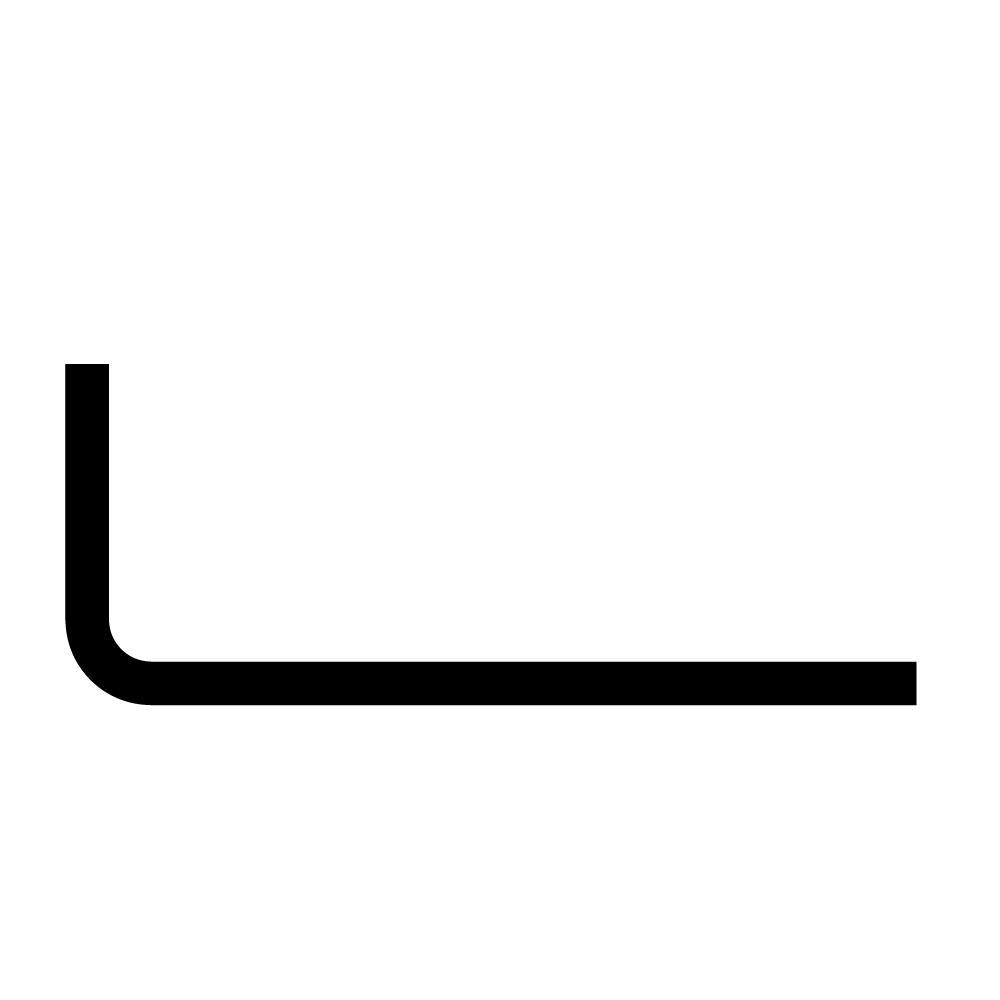

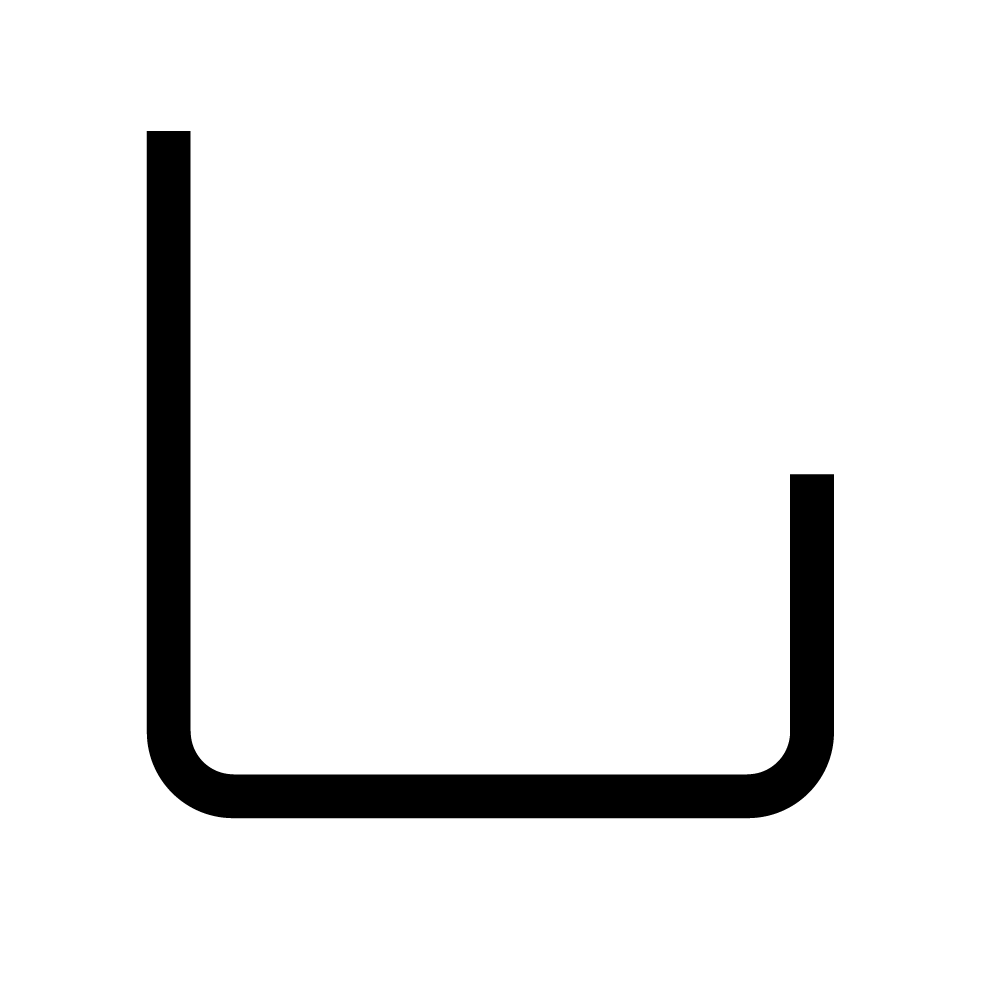

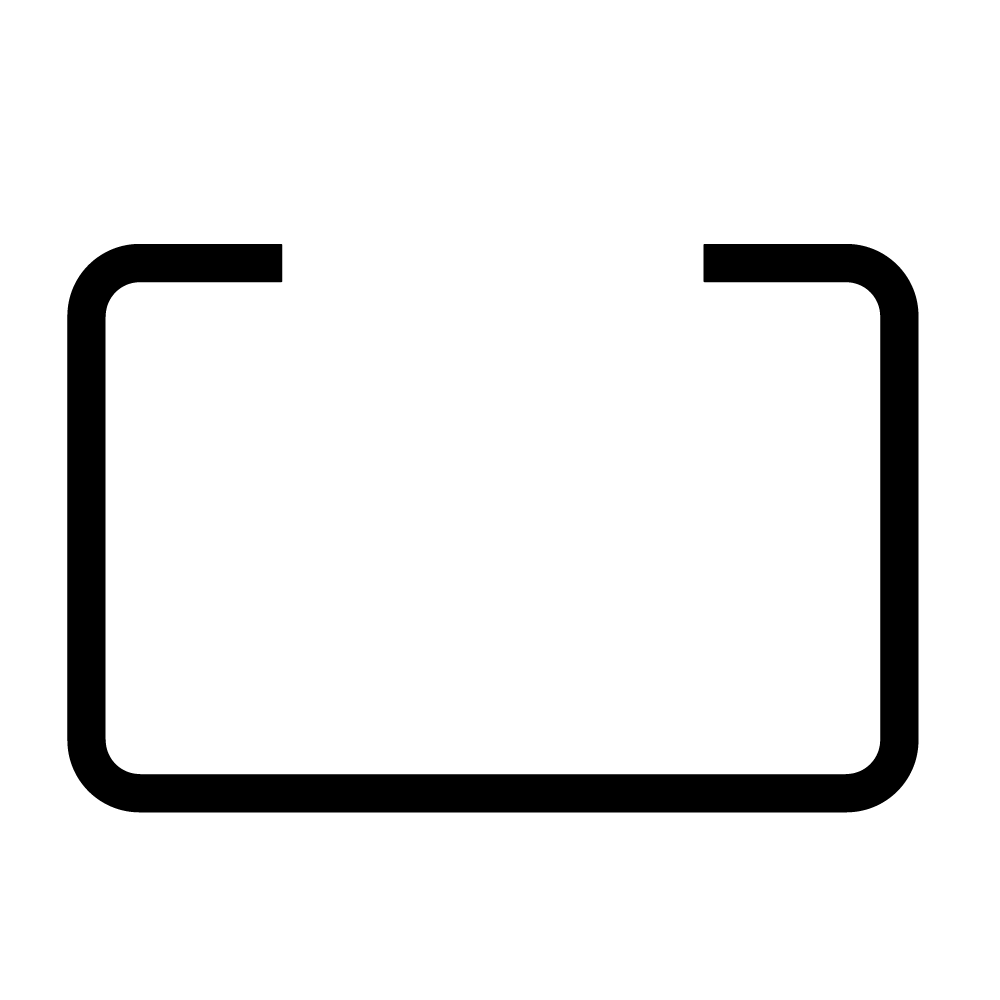

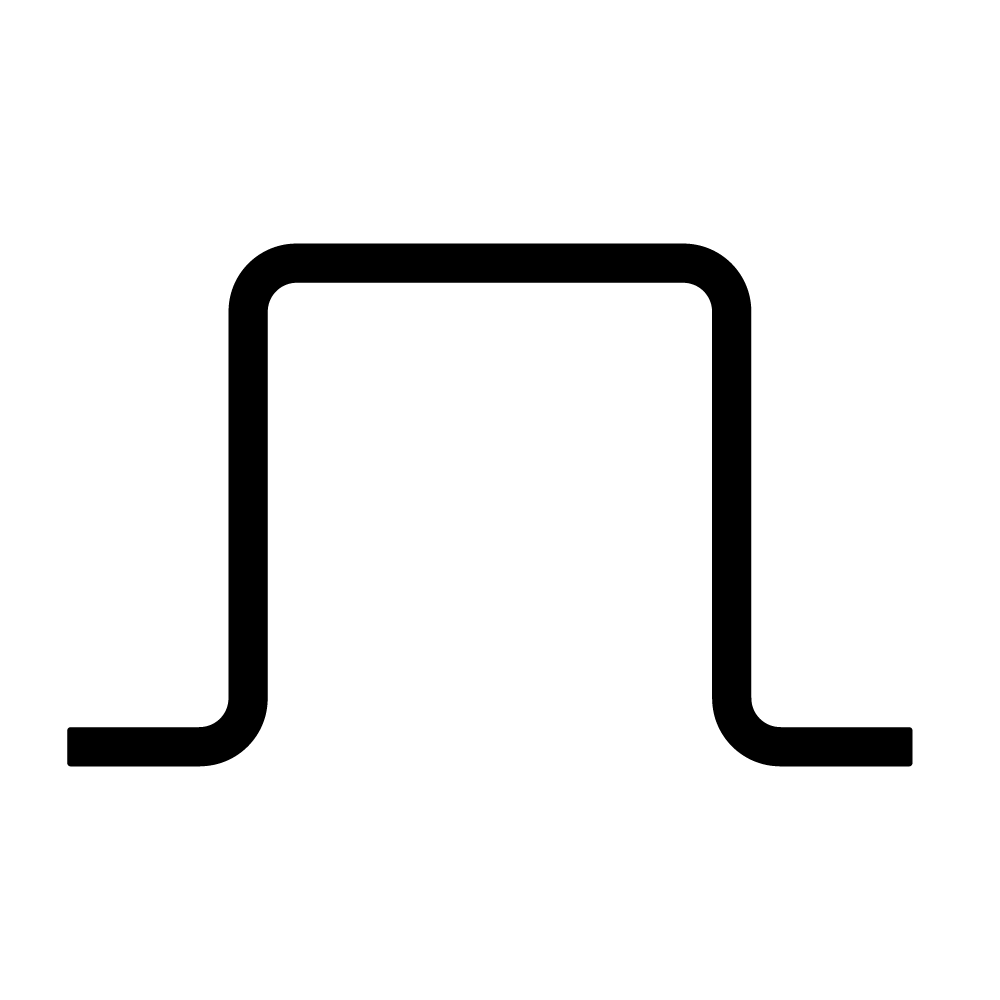

Steel starts in a flat sheet that is fed into the roll forming machine. If any pre-process punching is required, the steel first goes through the punch for holes and notches. Roller Die has the ability to make multiple punch patterns on the same line, saving time when making multiple parts from the same cross section.

The punched steel is then passed through a series of rollers to reach the desired cross-section. Roller Die is able to hold industry-standard tolerances and, in some cases, even tighter tolerance for industries that require a high degree of precision. Cut off dies at the end of the roll line ensure that the shape is accurate. Our team can also perform a variety of post-processing steps to further shape or finish your cold rolled steel part.

Roll Forming Standard Tooling Library Search for Cold Rolled Steel

Unable to find an exact match in our metal roll forming standard tooling library?

No problem.

With nearly 200 years of cumulative metal roll forming and shop experience, our engineers and in-house tool room can still meet your needs. Fill out our request for quote form to send specifications for your upcoming metal roll forming project and/or upload your CAD designs.

Roller Die + Forming News & Articles

How Steel Market Trends in 2025 Will Impact Manufacturers

As we look toward 2025, the steel market is poised for substantial transformation, bringing both challenges and opportunities for manufacturers. With rapidly advancing technologies and shifting consumer demands, the industry is evolving at an unprecedented pace. These changes are crucial for manufacturers to understand to stay competitive and efficient. The increasing emphasis on sustainability is […]

Why Roll Forming is Great for Manufacturers

Roll forming is a process that transforms metal into specific shapes using a series of rollers. This method creates products that are precise and consistent, making it vital for many industries. Manufacturers are increasingly turning to roll forming due to the numerous advantages it offers over other metalworking techniques. One key reason manufacturers favor roll […]