Innovation doesn’t equal high cost. We thrive on custom roll forming jobs and work as a proactive partner to produce results that are true to your designs and to your budget or experience and expertise which will help your business prosper. We are eager to build your custom roll formed solutions through our experience and expertise which will help your business prosper.

Custom Roll Forming Specialties

Creating custom roll formed shapes for clients is the daily business of Roller Die + Forming. We realize that innovation, catering to client needs, and flexibility are required for success in today’s demanding market. Our attention to detail ensures your custom roll formed shapes are formed to industry standard tolerances or better.

With a library of over 1,200 free tooling parts, we may already have your solution on hand. Our Engineering Department boasts well over 100 years of experience in creating and maintaining rollers. Over the last 60 years, we have built an extensive library of standard tooling that we can incorporate into our customer’s roll lines to significantly cut the cost of creating custom tooling. Please see our Standard Roll Formed Products section to search among tooling parts we have available for customer use.

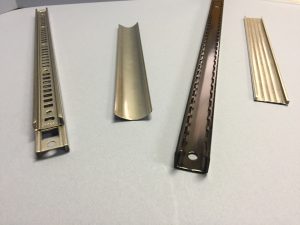

Roller Die specializes in creating custom roll formed parts to fit your needs. Generally, parts fall into five main types of roll formed shapes: Angles, Channels, Cee Sections, Hat Sections, and Z Sections. Additionally, we produce custom roll formed tubes. Our engineers can work with you to find a solution for more complex cross sections, even if it is a combination of these different styles.

Unable to find an exact match in our metal roll forming standard tooling library?

No problem.

With nearly 200 years of cumulative metal roll forming and shop experience, our engineers and in-house tool room can still meet your needs. Fill out our request for quote form to send specifications for your upcoming metal roll forming project and/or upload your CAD designs.

Roll Forming Materials

Almost any material that can tolerate bending to a desired radius can be roll formed. The more ductile the material is, the better it will roll form. The roll forming process can handle ferrous, nonferrous, hot rolled, cold rolled, polished, plated, or pre-painted metals producing excellent results.