If you need roll formed parts that have powder coating , we’ve ready for your business. To get started with your project, contact us today

Precision Powder Coating Services for Finished Goods

By finishing metal components with powder coating, you can make sure that the final product has a finish that is tougher and more resistant to corrosion than components finished with traditional liquid paints. Precision powder coating also provides efficiency and cost benefits, making it an excellent metal finishing process.

Powder coating provides benefits over traditional liquid finishing as it emits less hazardous waste. At Roller Die, we perform high-density powder coating using standard colors to maximize efficiency and keep the cost to our customers low. We recently increased our capacity and can now powder coat large parts.

The Benefits of Powder Coating

There are several types of metal assembly Roller Die + Forming can help in your manufacturing process. These include:

It makes the material or surface very durable and highly resistant to wear and tear.

It helps you achieve thicker, stronger, and specialty finishes.

It can be applied to a wide variety of materials, including most of the metals used in roll forming.

It has less impact on the environment compared to other forms of coatings.

Powder coated parts, materials, and surfaces are very easy to maintain and will serve the consumer for an extended period.

It can help save time and money.

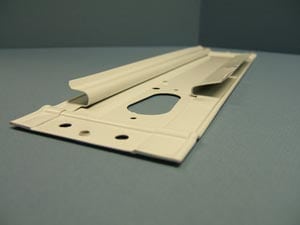

Our Powder Coated Solutions

At Roller Die + Forming, we offer a wide selection of powder-coated solutions, including primer coats, textured surfaces, clear coats, and colors. Our powder-coated solutions are guaranteed to protect your product and improve its visual appeal.

What’s more, our powder coated products can be used in many different functional applications, including in appliances, building products, automobiles, display and storage racks, furniture, and much more. We can deliver personalized solutions to meet your unique needs and product requirements.

Why Choose Our Powder Coating Services?

At Roller Die + Forming, we deliver high-quality craftsmanship and outstanding services to our esteemed customers. Here are some reasons to choose us to handle your roll forming and powder coating needs:

With more than 85 years of extensive experience, our company has emerged as an industry leader offering excellent, affordable, detailed, and outstanding customer services.

We work with a competent team of highly qualified and skilled experts. Our dedicated experts can deliver excellent powder coating jobs on your roll formed parts.

Roller Die + Forming remains the best provider of powder coating services. You can always count upon for the most competitive prices.

Our powder coating services are performed with a high level of quality and professionalism. The same consistent process that you take advantage of when having your part roll formed is also applied to powder coating. We offer you the best way to protect your product without compromising aesthetics.

Above all, we believe that anything worth doing is worth doing well. We will powder coat your products with the same high attention to detail and focus on quality control that goes into our roll forming. Thus, your powder-coated products will be strong, durable, and beautiful.

Roller Die + Forming News & Articles

Discover the Smart Ways to Use Custom Roll Formed Parts

Custom roll formed parts offer incredible benefits for a variety of industries. From automotive to construction, these parts provide strength, precision, and cost savings. Roll forming is a continuous bending operation, allowing for high-volume production of complex shapes with high dimensional accuracy. This process can handle both ferrous and non-ferrous metals, making it versatile for […]

Easy Tips for Managing Metal Supply Chains

Managing metal supply chains can be a complex task, but with the right strategies, it becomes much easier. A well-organized supply chain is crucial for manufacturers who rely on metals like steel and aluminum. These materials are essential for various applications, and any hiccups in the supply process can cause significant delays and increased costs. […]

Exciting New Roll Forming Tech for Manufacturers

Manufacturing is evolving, and so is roll forming technology. For those in the industry, staying updated with the latest advancements is essential. These innovations not only improve efficiency but also enhance product quality. Today’s roll forming machinery and techniques are more advanced than ever, offering manufacturers a range of benefits. From automated machines to real-time […]

- « Previous

- 1

- 2

- 3

- 4

- Next »