In addition, Aluminum Angles are produced with All Types of Finishes, from Standard Commercial Quality Mill Finish to Bright Annealed and Mirror Finishes. Contact us and we’d be happy to adapt your specific needs.

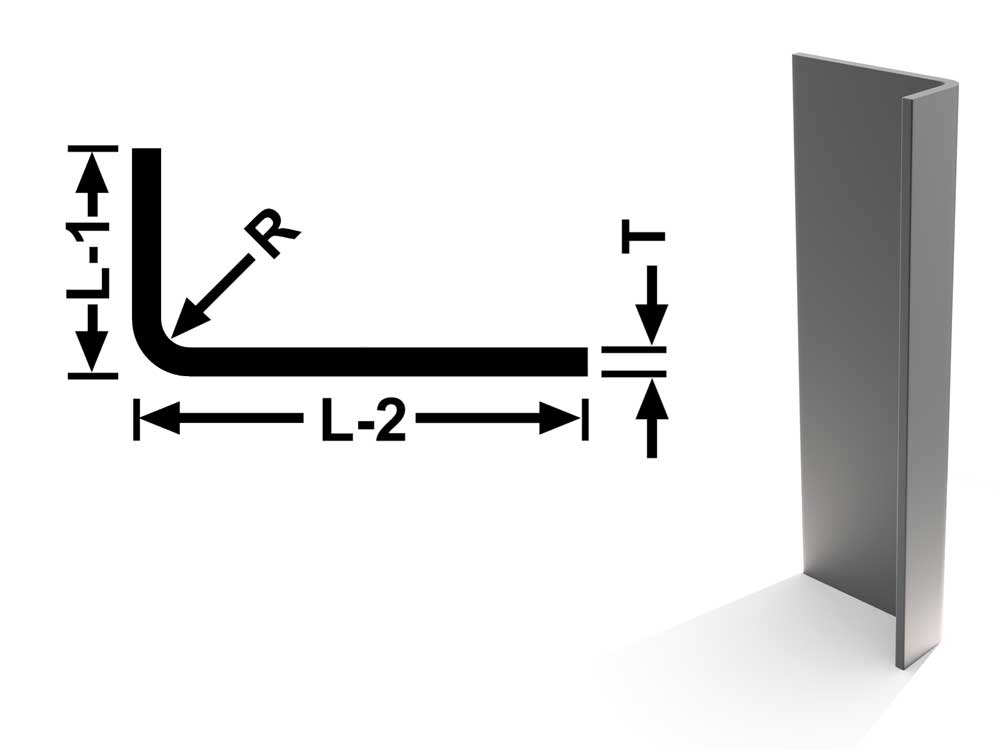

Roll Formed Aluminum Angles

Along with steel, aluminum roll forming makes up a large portion of Roller Die’s business. Our engineers understand when aluminum is preferable for a specific end product. Aluminum has approximately one-third the density of steel, which is often ideal for use in roll formed Aluminum Angles. Additionally, many end uses of Aluminum Angles demand a lighter metal, intended for structures that move. Another benefit of aluminum? All grades and finishes that are cold-workable at room temperature can be roll formed.

In addition, Aluminum Angles cater well to transportation vehicles — operating on Earth and beyond. These Angles and other roll formed shapes are especially active in the Aerospace, Automotive, Marine & Solar industries. Additionally, continued exploration of space and sea means Aluminum Angles will increase in popularity this century. Contact us to describe your upcoming Aluminum Angle project.

Unable to find an exact match in our metal roll forming standard tooling library?

No problem.

With nearly 200 years of cumulative metal roll forming and shop experience, our engineers and in-house tool room can still meet your needs. Fill out our request for quote form to send specifications for your upcoming metal roll forming project and/or upload your CAD designs.