At Roller Die + Forming, we offer sheet metal fabrication and assembly services. Our team of experts can handle virtually all types of metal assembly to your unique requirements. We use the best tools and processes to achieve accurate and highly durable parts, with no room for inconsistencies. From prototype to production, Roller Die + Forming remains your reliable partner for your various metal assembly needs.

ROLL FORMING: Major Advantages

Roll forming is superior to other metal forming processes and has advantages over aluminum extrusions, for many reasons.

Roll forming also makes it easier to produce longer lengths than are typically available on a stamping press. We can put holes in the part in-line, and we can provide you with the end cut you desire. The limiting factor on the length of a roll formed part is transportation, not the roll forming machine. We regularly roll parts that are 40-feet long.

Our engineers happily cater to all client needs, handling any job size with ease.

Custom Roll Forming Processes, Techniques, and Services

With roll forming services from Roller Die, your company can take advantage of an economical and efficient way of getting the metal components it needs. Our roll forming process features a team with decades of experience in the custom metal components business, allowing us to quickly produce strong metal components that are made to your exact specifications. We are also focused on technology and innovation and regularly invest in new equipment, software, and training to stay on top of changes in the industry.

The roll forming process works by passing sheet metal through a series of rollers, with each of these rollers adding shape to the metal. The rolls work together to form the desired cross-section. Since the process is consistent and easy to repeat, roll forming provides a great way to precisely produce very high volumes of metal components.

Our roll forming services, which include aluminum roll forming, can be used to create components for a wide variety of industries. In addition, we operate over 90 roll machines, with spindle sizes ranging from one inch to three inches. This means that we are able to quickly handle all your roll forming needs, whatever those needs might be. We can create both standard shapes and custom jobs, both of which are produced at the highest quality levels possible.

To get started with your custom roll forming project, contact us today for a free quote.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

There are two common roll forming techniques with variations:

1) Pre-cut or cut-to-length roll forming

- Strips are pre-cut and processed, then fed into the roll former as individual strips. These strips may be cut from a coil or sheet.

- Processing may include piercing, notching, embossing.

- Typically used for low-production parts or parts with certain types of notches.

2) Post-cut roll forming

- Pieces of the cross section are cut to length after forming. This process involves working from a coil of material.

- A strip can be pierced, notched, or further processed before the cutoff operation.

- The cut-off system moves with the strip and can add other features.

Roll Forming Materials

Almost any material that can tolerate bending to a desired radius can be roll formed. The more ductile the material is, the better it will roll form. The roll forming process can handle ferrous, nonferrous, hot rolled, cold rolled, polished, plated, or pre-painted metals producing excellent results.

Almost any material that can tolerate bending to a desired radius can be roll formed. The more ductile the material is, the better it will roll form. The roll forming process can handle ferrous, nonferrous, hot rolled, cold rolled, polished, plated, or pre-painted metals producing excellent results.

Material Spec Qualification:

- Materials as thin as 0.005″ can be roll formed.

- Material pieces as narrow as 1/8 “ and as wide as 72″ or more can be roll formed, depending on machine size.

- Roller Die’s range of materials is:

- .005″ to .187″ thick

- .500″ to 20.00″ wide

Roll Forming Standard Tooling Library Search

Unable to find an exact match in our metal roll forming standard tooling library?

No problem.

With nearly 200 years of cumulative metal roll forming and shop experience, our engineers and in-house tool room can still meet your needs. Fill out our request for quote form to send specifications for your upcoming metal roll forming project and/or upload your CAD designs.

Roll Forming Examples From Roller Die’s

#1 Fairing Support Rail – 7835

- .071″ G90 HDG

- 20 roll passes on 2″ mill

- All holes pre-notched, repeating pattern with multiple lengths

- Parts powder coated black

- Multiple angles in a relatively heavy gauge

- Straightness, twist, bow, flatness of this section is very critical – total indicator reading for flatness

#2 Rear Window Shade Toyota Camry – 7824

- CRS 0.029″ thick

- 24 passes

- Pre-notch, part complete off roll machine

- Very difficult section

- Very close tolerances on slots and holes

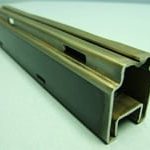

#3 Main Frame For Office Partition – 7864

- 0.056″ thick CRS

- Uses 26 pass roll line

- Uses striped pre-painted steel

- Location of striping critical due to welding process

- Difficult roll section due to shape and need to keep section uniform

- Twist, bow, and straightness critical

- Tolerances and shape of section critical to customer assembly

Design Considerations

Bend Radii:

- Best practice is a one metal thickness inside radius

- May need to be slightly larger in high strength steels

- Sharper corners can be obtained at the expense of tool life

- Scoring the inside of the strip can help make sharper corners in some cases

Deep Sections:

- Require more passes, larger machines, and larger rolls and dies

- Risk overstressing the edges of the material

- Typical machines – 100 mm max

Short Legs:

Three times metal thickness is a good minimum leg length

Wide Sections:

- Apply ribs to offsets on wide panels

- Helps prevent wrinkles and “oil-canning”

- Often wide material has appearance issues

Cross Section Tolerances:

- Typically +/- .25 mm to +/- .75 mm

- Tighter tolerances are achievable: a) different approach to tooling and b) special quality materials

- Angular tolerances; typically +/- 1 degree

Length Tolerances:

- Influenced by factors, including length of part, speed of rollformer, measuring system, cutoff system, and material properties

- Commonly available: +/- 0.8 mm

- Special equipment and tooling: +/- 0.25 mm

- Long parts (3M or more): +/- 3.0 mm and up

Straightness:

- Bow (up or down)

- Curve (side to side) – 1.0 mm per meter

- Twist – 1 degree per meter

Flare:

- Typically avoid measuring the cross section within 50 mm or ends

- Flare can be controlled with special attention

Roller Die + Forming News & Articles

Best Practices for Custom Roll Formed Products

Custom roll forming is a specialized process that shapes metal strips into specific profiles using continuous bending operations. This method is highly efficient for producing large quantities of consistent and precise metal parts. It is widely used in various industries including automotive, construction, and electronics due to its versatility and cost-effectiveness. Understanding the ins and […]

Why Recycled Metals Matter in Manufacturing

Recycling metals is transforming the manufacturing industry. Many manufacturers find that using recycled metals offers numerous benefits beyond cost savings. From environmental advantages to quality performance, recycled metals are essential in various sectors. Understanding these benefits is crucial for manufacturers looking to stay competitive and sustainable in 2025. Benefits of Using Recycled Metals in Manufacturing […]

Why Recycled Metals Matter in Manufacturing

Recycling metals is transforming the manufacturing industry. Many manufacturers find that using recycled metals offers numerous benefits beyond cost savings. From environmental advantages to quality performance, recycled metals are essential in various sectors. Understanding these benefits is crucial for manufacturers looking to stay competitive and sustainable in 2025. Benefits of Using Recycled Metals in Manufacturing […]

- « Previous

- 1

- 2

- 3

- 4

- Next »