The solar energy industry is experiencing rapid growth, driven by global concerns over climate change, depleting fossil fuel resources, and an increasing demand for clean and renewable energy alternatives. Custom roll formed products play a vital role in enabling the development and maintenance of solar power systems by providing high-quality, versatile, and cost-effective components. Custom […]

Roll Formed Stainless Steel

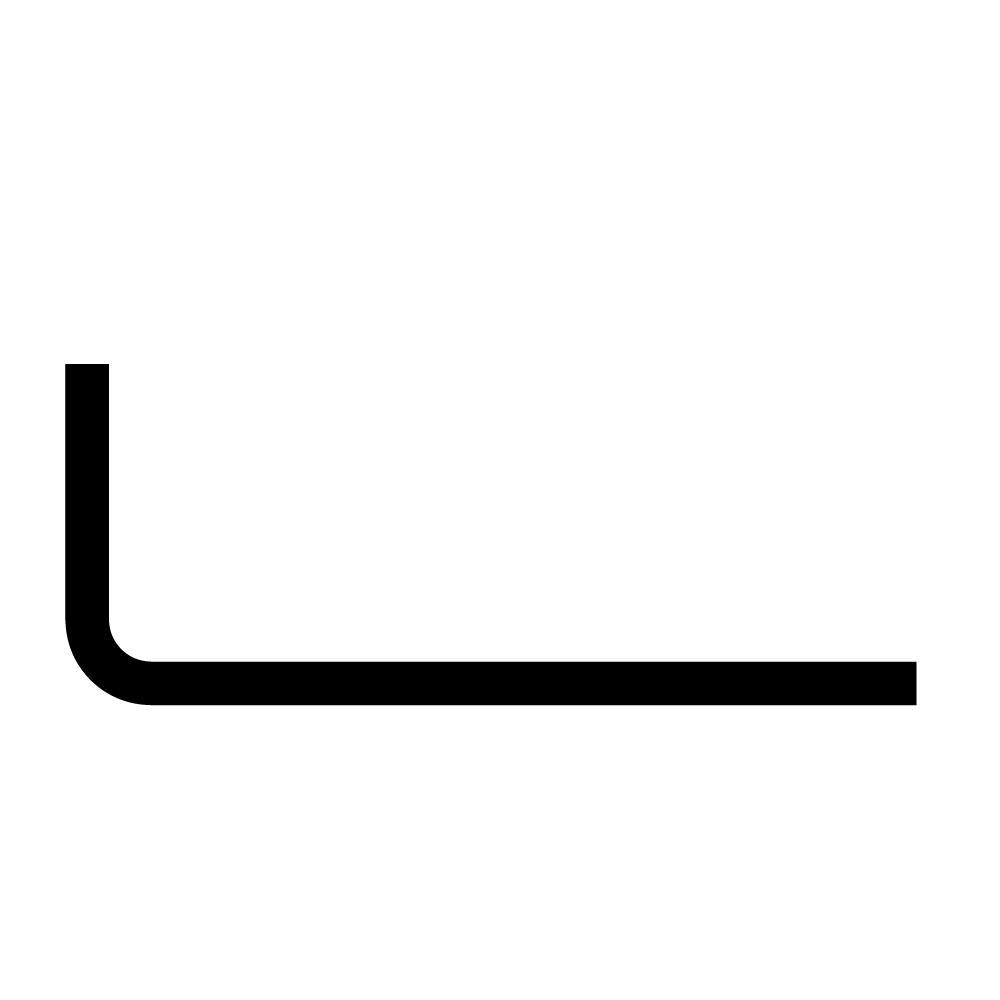

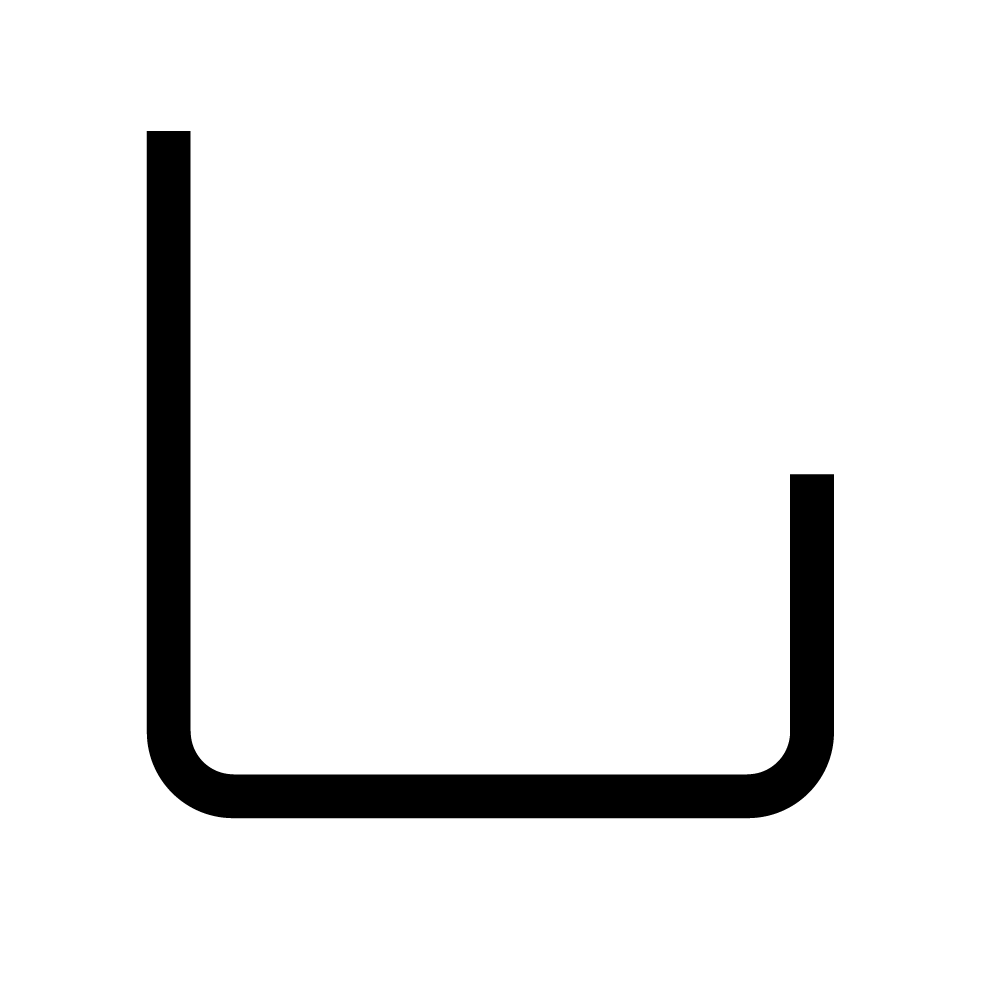

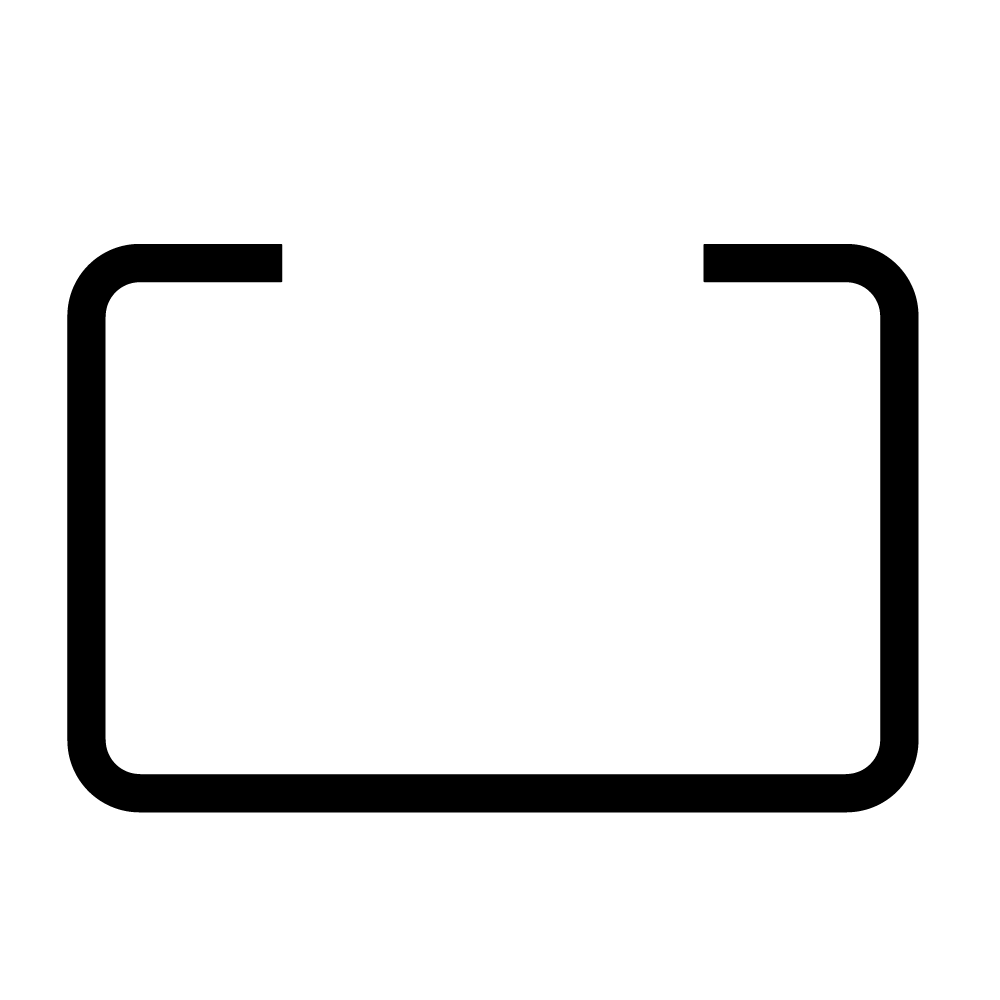

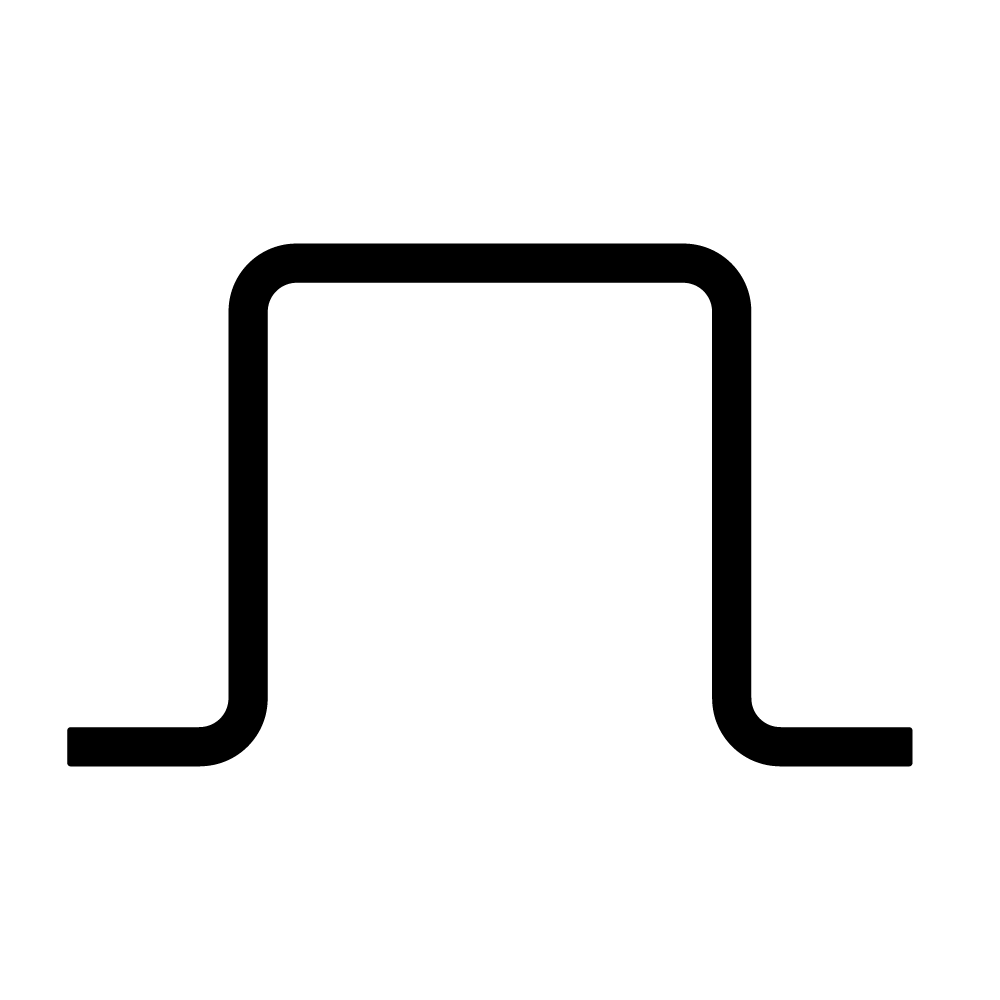

Steel roll forming is an excellent choice for high volume projects as it provides excellent cost efficiency. An additional benefit is that steel roll forming does not degrade the strength of the part, so it delivers the strength required for best use of the end product. Stainless steel parts are rolled and protected so that their shiny side remains attractive for consumer parts.

Stainless steel roll forming offers distinct advantages that result from the characteristics of stainless steel. Stainless steel is typically used for its mechanical properties and corrosion resistance as well as its attractive finish. Stainless steel roll forming is used in the manufacture of products such as medical devices, food handling equipment, dairy equipment, chemical equipment, marine-grade parts, and more.

Roller Die provides the best materials and price for stainless steel roll forming projects. Our team is experienced in working with stainless steel and understand how to ensure your parts shine.

Roll Forming Standard Tooling Library Search for Stainless Steel

Unable to find an exact match in our metal roll forming standard tooling library?

No problem.

With nearly 200 years of cumulative metal roll forming and shop experience, our engineers and in-house tool room can still meet your needs. Fill out our request for quote form to send specifications for your upcoming metal roll forming project and/or upload your CAD designs.

Roller Die + Forming News & Articles

Strengthening Infrastructure: Custom Roll Formed Products in the Construction Industry

The construction industry is a cornerstone of the global economy, driving urban development, improving infrastructure, and providing essential facilities for communities worldwide. As a result, the sector continuously requires materials and processes to optimize efficiency, lower costs, and enhance the overall quality and durability of construction projects. Custom roll formed products play a significant role […]

Building a Greener Future: Custom Roll Formed Products in Sustainable Construction

The construction industry plays a critical role in shaping our built environment, with significant implications for both ecosystems and communities. As concerns about climate change and resource depletion continue to grow, there is an increasing emphasis on sustainable construction methods and materials. Custom roll-formed products are invaluable components in green building projects, offering a range […]

- « Previous

- 1

- 2

- 3

- 4