U Channels are produced with All Types of Finishes, from Standard Commercial Quality Mill Finish to Bright Annealed and Mirror Finishes. We can also create Steel U channels as well as many other metals with our Roll Forming Process. Contact us and we’d be happy to adapt your specific needs.

Roll Formed U Channels & Hat Channels

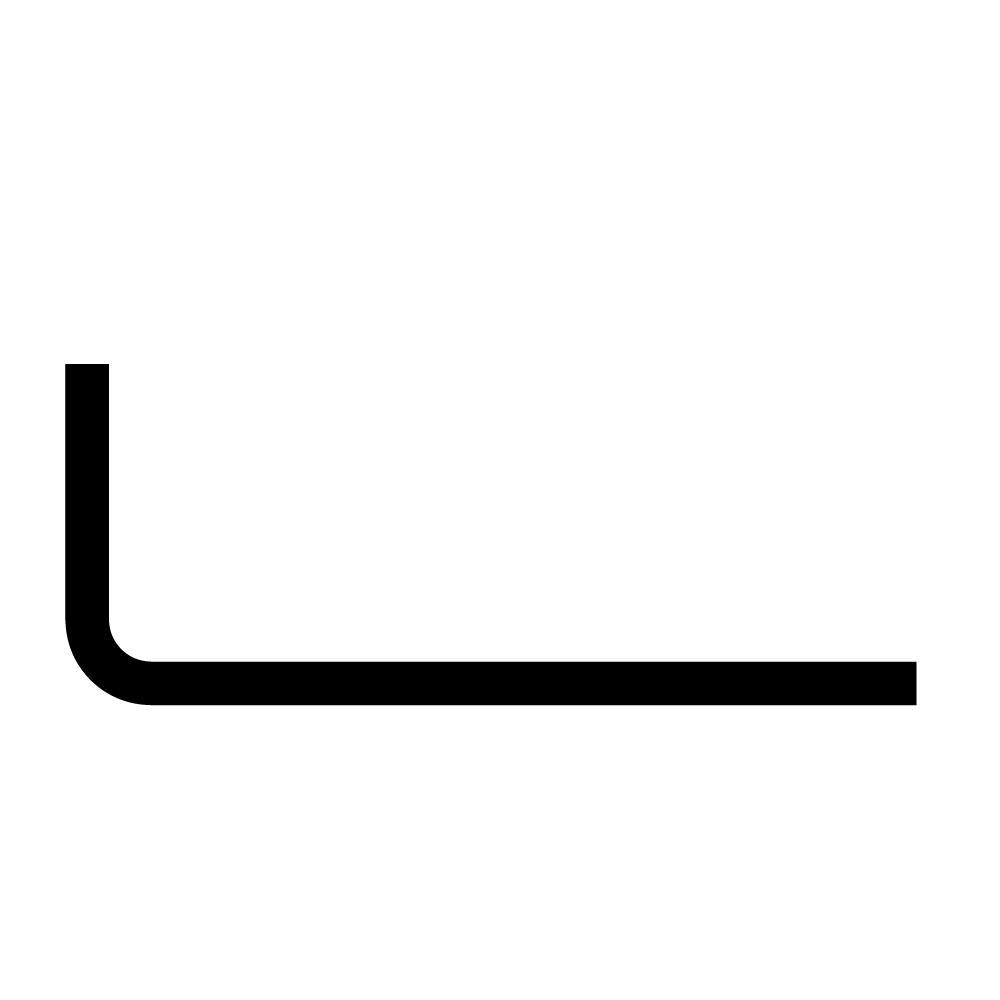

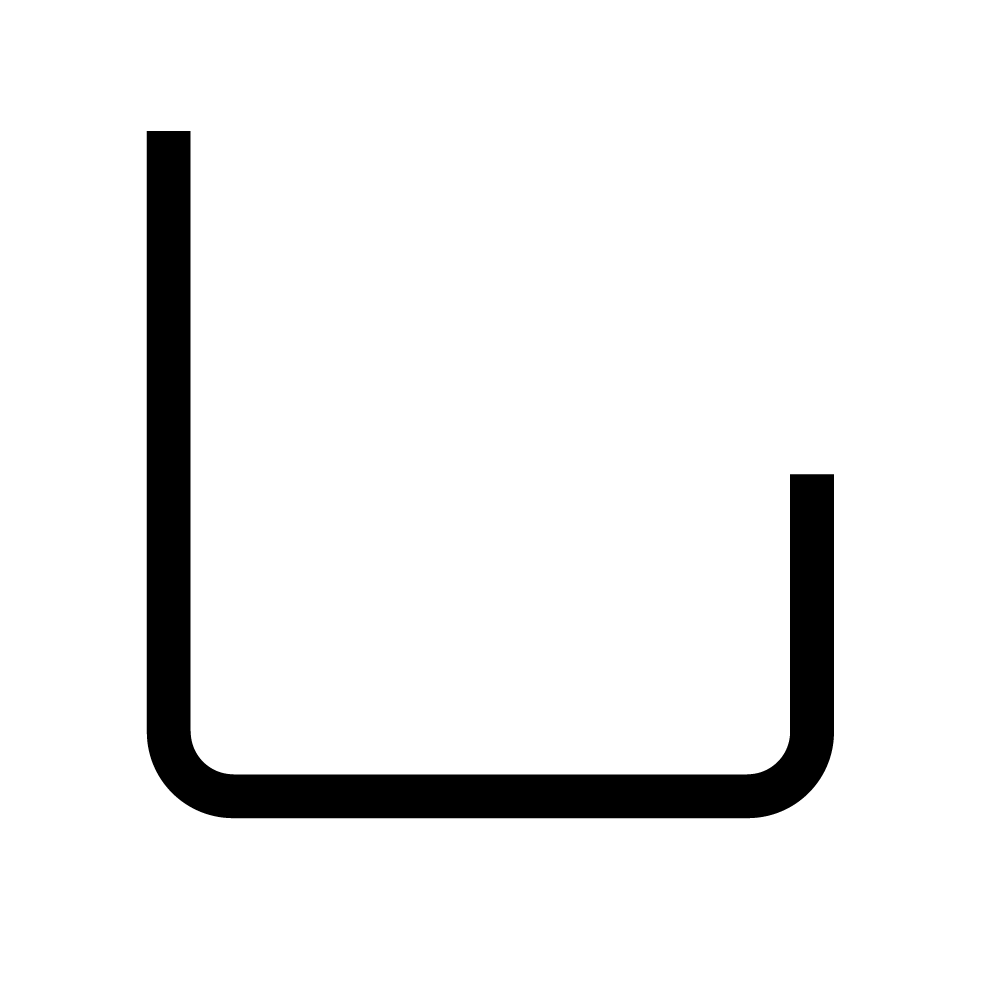

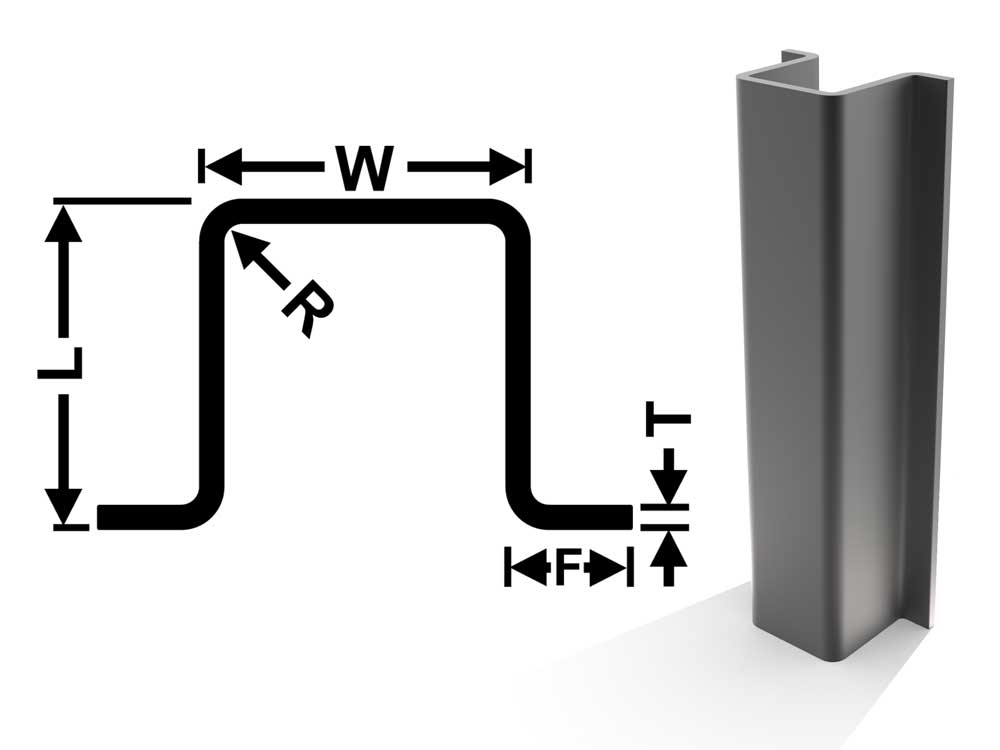

U-Channels are a roll formed shape similar to J-Channels, with the main difference being that their open sides are of equal length. U Channels (including Hat Channels) and J-Channels often require extra inline fabrication during the roll forming process, all of which Roller Die can handle with our well maintained roll form lines.

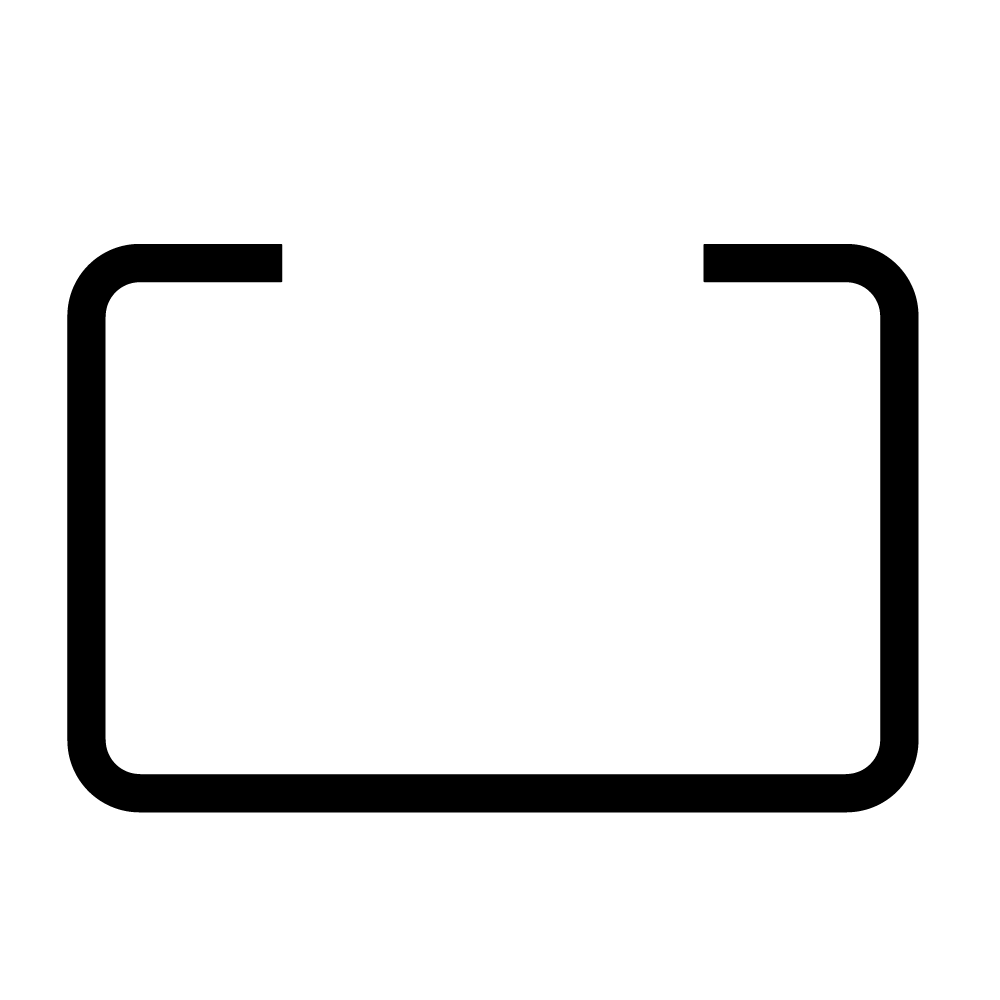

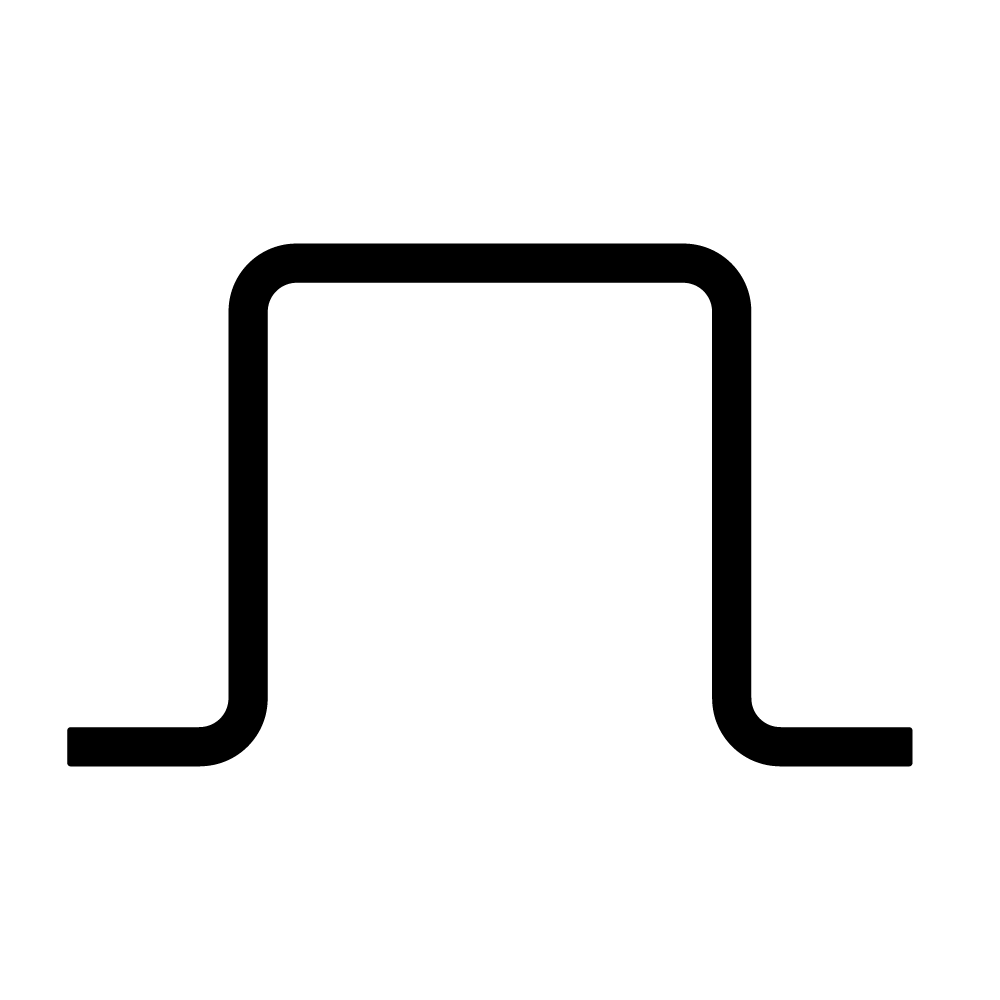

Hat Channels, which are a type of U Channel, look exactly as their name suggests, like a top hat. The Hat Channel is composed of two outward flanges (the brim), plus two vertical dimensions (the sides of the hat). Another description would be that Hat Channels are roll formed U Channels, with the bottom (or horizontal web) perpendicular to two vertical legs containing outward flanges. These flanges are also referred to as “wings” or “fins.”

Our roll form machines provide a smooth, attractive finish, can hold extremely tight tolerances, and provide sharp contours. As always, our standard tooling library is available to help offset tooling costs and our expert engineers can manage any steel U Channels (including Hat Channels) dimensions not listed in our standard tooling lists.

U Channel: Thickness Ranges

- .018″ – .194″ (Nominal)

U Channel: Tolerance Capabilities

- Cross-Sectional Standard Tolerances: +/-.031″

- Angularity: +/- 1 degree

- Straightness: Maximum Deviation of .015″/ft

- Twist: Maximum Deviation of 1/4 degree per ft

U Channel: Length Tolerances

- Length up to 36″ : +/-.030″

- Lengths 36″ to 120″ : +/-.060″

- Length 120″ to 240″ : +/-.125″

- Lengths greater than 240″ : +/-.250″

**Note: In some cases, closer tolerances than the standard (listed above) can be achieved, but may require additional tooling.

Additional Capabilities

- Pre- and Post-Process Hole Piercings

- Inline Flying Cutoff Providing Parts Cut to Finished Length

- Stampings

- Welding

- Secondary Punching +ACY- Forming Operations

- Assembly

- Special Packaging

Roll Forming Standard Tooling Library

Roller Die + Forming Additional Services

Unable to find an exact match in our metal roll forming standard tooling library?

No problem.

With nearly 200 years of cumulative metal roll forming and shop experience, our engineers and in-house tool room can still meet your needs. Fill out our request for quote form to send specifications for your upcoming metal roll forming project and/or upload your CAD designs.