At Roller Die + Forming, we offer Aluminum Extrusion services. Our team of experts can handle virtually all types of aluminum extrusion to your unique requirements. We use the best tools and processes to achieve accurate and highly durable parts, with no room for inconsistencies. From prototype to production, Roller Die + Forming remains your reliable partner for your various extrusion needs.

Aluminum Extrusion vs. Roll Forming

Challenge: A potential customer found the RDF website through an Internet search. After a review of our extensive capabilities, an inquiry was submitted for assistance with a complete conveyor system redesign.

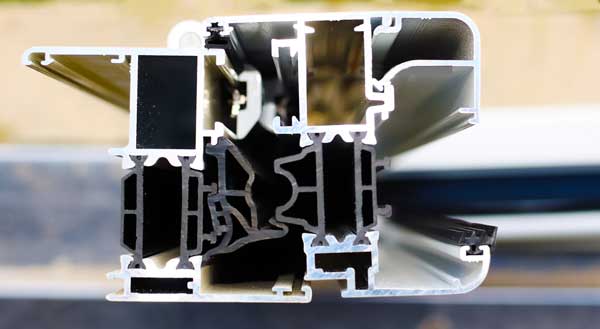

This customer wanted to convert a very costly aluminum extrusion system to a much more manufacturing friendly roll formed system, produced in a quarter-hard stainless steel. With the current supply chain for this system located in Europe, the customer focus was on a two-fold cost reduction initiative: roll formed shapes of the highest quality, produced in the US (roll forming shapes vs aluminum extrusion).

Solution: Through numerous conference calls and concept design sessions, we were able to develop a concept consisting of just a single roll formed shape.

This easily roll formed shape could be mirrored back-to-back, utilizing any two parts yielded at the production line. These two parts would then be spot welded together down the length of the part. This process essentially replicated the tightly toleranced aluminum extrusion design, but at a fraction of the price. Additionally, the strict quality standards Roller Die implemented and repeatability were maintained on critical parts where consistency is the key to success.

Result: The lower cost solution has since paved the way for a much more price-competitive system in the marketplace, and sales for this system have seen substantial growth over the past year. Currently, we are working with this customer on a new project of similar scope, and are continuing to build a solid, long-term customer relationship, while also still providing those win-win solutions.

Roller Die + Forming News & Articles

Roller Die + Forming and the Material Handling Industry

Roller Die + Forming frequently works within the material handling industry. Material handling is the movement, protection and storage of materials and products through warehousing, distribution, consumption and disposal. Material handling incorporates a wide range of manual, semi-automated and automated equipment and systems that support supply chain and logistics. Essential to Success Material handling […]

Roller Die Makes Parts from Many Metals

While we talk a lot about steel roll forming, all the different shapes we can make from steel, and the advantages of cold rolled steel to many markets, don’t forget we can roll form other metals as well. In fact, aluminum roll forming is a common way to create light aluminum parts for appliances, decorative […]

Rolling into 2021: Roller Die’s Projections

The last year brought unexpected challenges and a global situation that no one expected. Everyone at Roller Die + Forming was happy to celebrate the new year and is looking into 2021 with excitement. There are a couple of key trends our team is focused on, making 2021 look like a promising year for those […]

- « Previous

- 1

- …

- 4