The material handling industry is a critical component in the supply chain, facilitating the seamless movement, storage, and management of goods within various sectors. As the demand for efficient and reliable material handling solutions grows, manufacturers and service providers in the industry are continuously seeking ways to optimize their processes and equipment for maximum performance, durability, and cost-effectiveness. At the forefront of this pursuit for optimization is the integration of advanced manufacturing techniques, and custom roll formed products offer a highly effective solution for revolutionizing material handling solutions.

Roller Die + Forming, a leading supplier of top-quality, competitively priced custom roll formed products, has extensive experience in providing the material handling industry with innovative metal solutions tailored to their unique needs. By partnering with Roller Die + Forming, manufacturers and service providers can access an unparalleled range of custom roll formed components designed to enhance the efficiency, durability, and performance of material handling equipment and processes.

By incorporating custom roll formed products into material handling solutions, Roller Die + Forming is dedicated to supporting the growth and efficiency of this critical industry. This commitment ensures that our clients have access to the most advanced and effective metal components available, empowering them to excel in their respective sectors and make a lasting impact on the material handling landscape.

Enhancing Material Handling Solutions with Custom Roll Formed Products: Efficiency, Durability, and Performance

Applications of Custom Roll Formed Products in Material Handling

Custom roll formed products offer a wealth of applications for the material handling industry, enabling the optimization of equipment and processes for increased efficiency, durability, and performance:

- Racking and Shelving Systems: Custom roll formed components provide the structural support and strength required for efficient and space-saving racking and shelving solutions, designed to accommodate diverse storage requirements and maximized warehouse utilization.

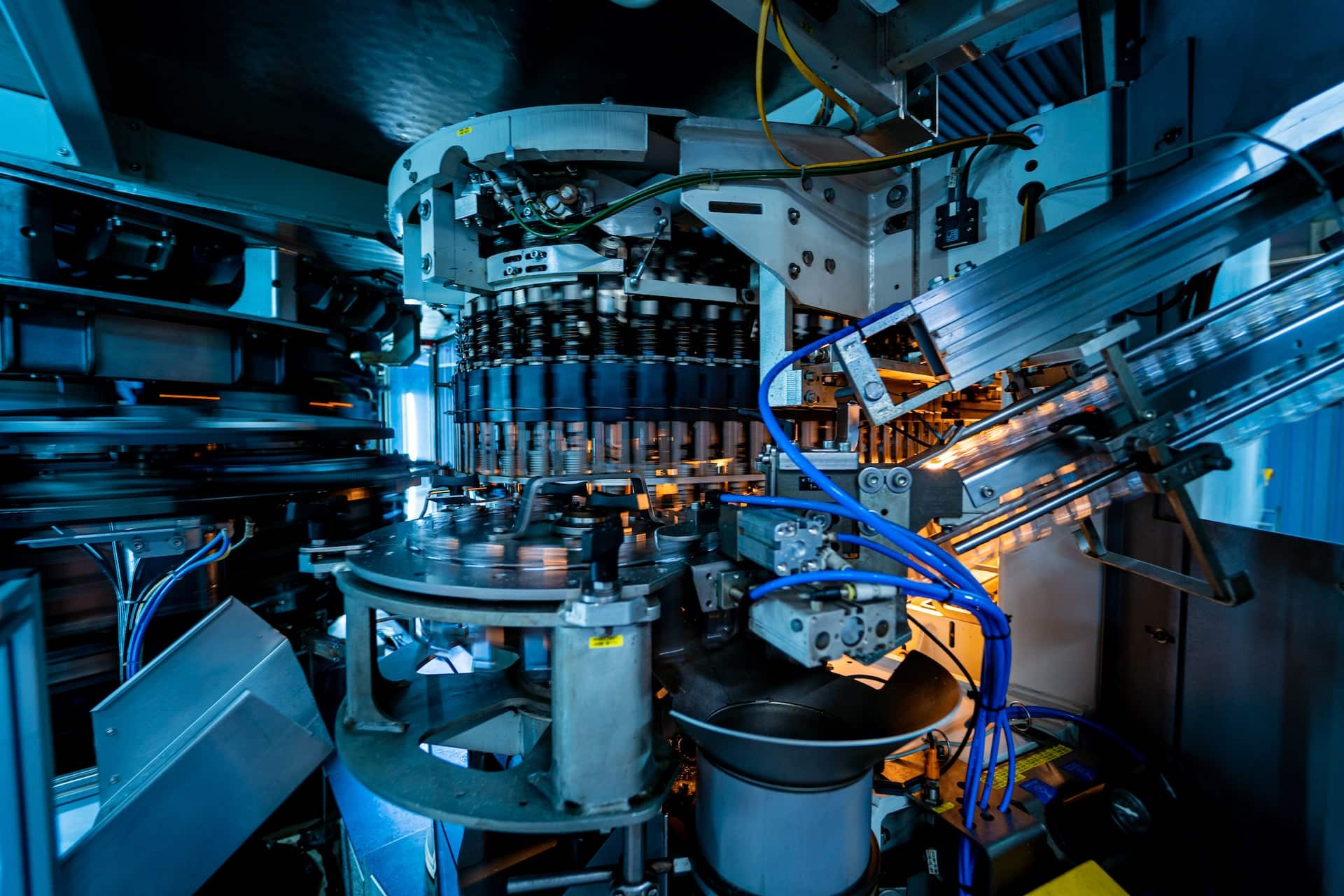

- Conveyor Systems: Roll formed components are essential to the design and function of conveyor systems, offering lightweight and durable solutions for roller tracks, support frames, and guide rails, ensuring efficient movement of goods throughout the material handling process.

- Automated Storage and Retrieval Systems (AS/RS): Custom roll formed components play a vital role in the construction and functionality of automated storage and retrieval systems, contributing to the stability and precision of this innovative material handling technology.

- Protective Bumpers and Guard Rails: Utilizing custom roll formed products for protective bumpers and guard rails can help safeguard both personnel and equipment, maintaining a safe and efficient work environment.

Material and Design Considerations for Custom Roll Formed Products in Material Handling

Selecting the appropriate materials and designs for custom roll formed components is essential for achieving the desired efficiency, durability, and performance standards in material handling applications:

- High-Strength Steel: Utilizing high-strength steel alloys offers advantages in terms of weight reduction and increased strength, ensuring the structural integrity and efficiency of racking and conveyor systems.

- Corrosion-Resistant Metals: Materials such as stainless steel and aluminum provide excellent corrosion resistance and durability, making them ideal choices for components exposed to harsh environments or rigorous use in material handling operations.

- Custom Profiles and Geometries: Roll forming enables the creation of custom profiles and geometries tailored to specific material handling equipment needs, optimizing the performance and adaptability of various systems.

- Coatings and Finishes: Choosing the right coatings and finishes for custom roll formed products can enhance the durability and resistance of components, extending their lifespan and reducing the need for maintenance.

Benefits of Custom Roll Forming for Material Handling Industry

Custom roll forming offers numerous advantages for the material handling industry, allowing for the development of innovative, high-strength, and cost-effective metal solutions:

- Design Flexibility: Roll forming allows for the production of complex geometries and profiles, providing the material handling industry with the design flexibility necessary to create innovative and efficient equipment and systems.

- Material Efficiency: By using pre-cut strips and coils, roll forming processes reduce waste and maximize material utilization, offering cost-effective production methods and increased sustainability.

- Scalability: Custom roll forming is scalable, enabling manufacturers to quickly adjust production quantities in response to changes in market demand, maintaining cost efficiency and responsiveness.

- Quality and Precision: Roll forming technology ensures tight tolerances and exceptional component quality, resulting in optimal performance and a strong return on investment for material handling manufacturers.

The Future of Material Handling Industry and Custom Roll Formed Solutions

As the material handling industry continues to evolve and advance, custom roll formed products have the potential to significantly impact the sector’s growth and development:

- Industry 4.0 and Advanced Automation: Custom roll formed components can support the implementation of Industry 4.0 and advanced automation in material handling facilities, enhancing the efficiency and adaptability of processes and equipment.

- E-commerce and Warehousing: The rise of e-commerce is driving demand for efficient warehousing and material handling systems, with custom roll formed products playing a key role in optimizing racking, conveyor, and AS/RS solutions.

- Green and Sustainable Solutions: Custom roll forming’s efficient material utilization and capability to use recycled metals contribute to the industry’s shift towards eco-friendly, sustainable practices.

- Adaptability to Market Demands: Custom roll formed solutions can accommodate changing market demands, such as the diversification of product types and the need for flexible and modular material handling systems.

Revolutionizing the Material Handling Industry with Custom Roll Formed Solutions

Custom roll formed products have a significant role to play in the ongoing evolution and advancement of the material handling industry, providing the high-strength, cost-effective, and innovative metal solutions necessary for success in a competitive market. By partnering with Roller Die + Forming, manufacturers and service providers can leverage the transformative potential of custom roll forming technology to enhance the efficiency, durability, and performance of their material handling equipment and processes.

As a premier supplier of custom roll form products, our mission is to ensure clients have access to the advanced and versatile metal components that will shape the future of material handling.