If you need roll formed parts that have powder coating , we’ve ready for your business. To get started with your project, contact us today

Precision Powder Coating Services for Finished Goods

By finishing metal components with powder coating, you can make sure that the final product has a finish that is tougher and more resistant to corrosion than components finished with traditional liquid paints. Precision powder coating also provides efficiency and cost benefits, making it an excellent metal finishing process.

Powder coating provides benefits over traditional liquid finishing as it emits less hazardous waste. At Roller Die, we perform high-density powder coating using standard colors to maximize efficiency and keep the cost to our customers low. We recently increased our capacity and can now powder coat large parts.

The Benefits of Powder Coating

There are several types of metal assembly Roller Die + Forming can help in your manufacturing process. These include:

It makes the material or surface very durable and highly resistant to wear and tear.

It helps you achieve thicker, stronger, and specialty finishes.

It can be applied to a wide variety of materials, including most of the metals used in roll forming.

It has less impact on the environment compared to other forms of coatings.

Powder coated parts, materials, and surfaces are very easy to maintain and will serve the consumer for an extended period.

It can help save time and money.

Our Powder Coated Solutions

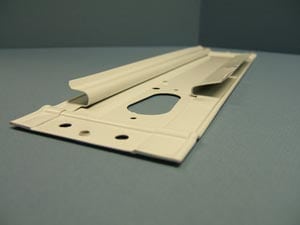

At Roller Die + Forming, we offer a wide selection of powder-coated solutions, including primer coats, textured surfaces, clear coats, and colors. Our powder-coated solutions are guaranteed to protect your product and improve its visual appeal.

What’s more, our powder coated products can be used in many different functional applications, including in appliances, building products, automobiles, display and storage racks, furniture, and much more. We can deliver personalized solutions to meet your unique needs and product requirements.

Why Choose Our Powder Coating Services?

At Roller Die + Forming, we deliver high-quality craftsmanship and outstanding services to our esteemed customers. Here are some reasons to choose us to handle your roll forming and powder coating needs:

With more than 85 years of extensive experience, our company has emerged as an industry leader offering excellent, affordable, detailed, and outstanding customer services.

We work with a competent team of highly qualified and skilled experts. Our dedicated experts can deliver excellent powder coating jobs on your roll formed parts.

Roller Die + Forming remains the best provider of powder coating services. You can always count upon for the most competitive prices.

Our powder coating services are performed with a high level of quality and professionalism. The same consistent process that you take advantage of when having your part roll formed is also applied to powder coating. We offer you the best way to protect your product without compromising aesthetics.

Above all, we believe that anything worth doing is worth doing well. We will powder coat your products with the same high attention to detail and focus on quality control that goes into our roll forming. Thus, your powder-coated products will be strong, durable, and beautiful.

Roller Die + Forming News & Articles

Roller Die + Forming Purchases Assets of Redall Industries in Yale, Michigan

Rapidly growing custom metal forming company Roller Die recently purchased the assets of Redall Industries, a roll forming facility located in Yale, Michigan. 12/30/24 – Roller Die + Forming recently completed an asset purchase from Redall Industries, located in Yale, Michigan. This existing roll form facility has a number of advanced manufacturing technologies and will […]

How Steel Market Trends in 2025 Will Impact Manufacturers

As we look toward 2025, the steel market is poised for substantial transformation, bringing both challenges and opportunities for manufacturers. With rapidly advancing technologies and shifting consumer demands, the industry is evolving at an unprecedented pace. These changes are crucial for manufacturers to understand to stay competitive and efficient. The increasing emphasis on sustainability is […]

Why Roll Forming is Great for Manufacturers

Roll forming is a process that transforms metal into specific shapes using a series of rollers. This method creates products that are precise and consistent, making it vital for many industries. Manufacturers are increasingly turning to roll forming due to the numerous advantages it offers over other metalworking techniques. One key reason manufacturers favor roll […]