Roll forming is renowned for its high speed and efficiency, making it a preferred method for producing steel channels and other profiles. This speed offers several advantages to Roller Die’s customers, including increased productivity, cost savings, and shorter lead times.

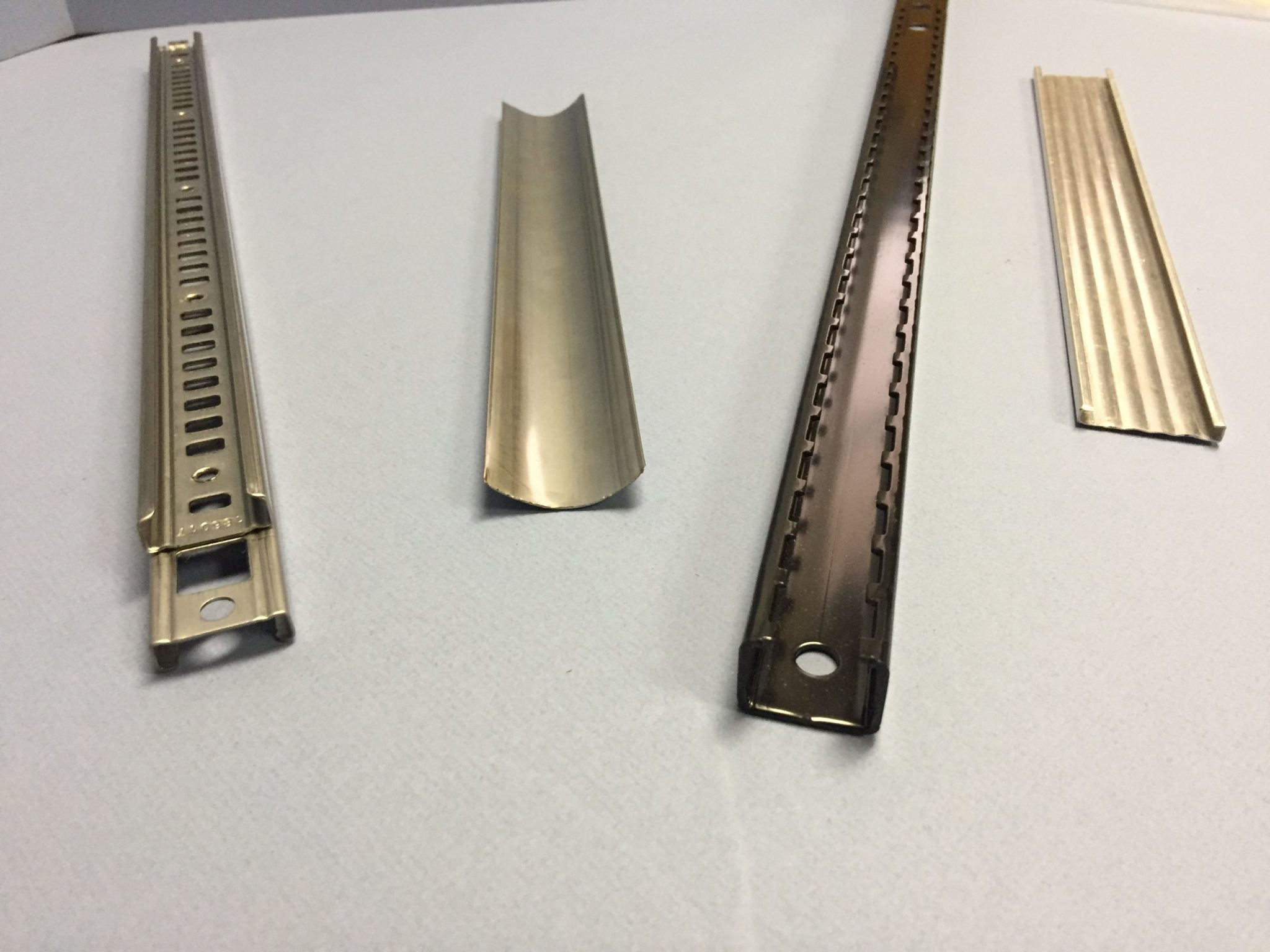

One of the primary benefits of roll forming’s high speed is enhanced productivity. The process can rapidly transform raw steel strips into finished channels, flowing through the rollers in a continuous manner. The continuous nature of roll forming eliminates the need for individual cutting and forming operations, resulting in a faster production cycle. Roller Die also has several in-line processes including punching. This efficiency allows manufacturers to produce a significant volume of steel channels within a short timeframe, meeting high-demand requirements and maximizing output.

By reducing the overall production time, manufacturers can optimize their resources and increase production capacity. This improved efficiency translates into lower labor costs, as fewer operators are required. Additionally, the continuous operation of roll forming minimizes material waste, as it eliminates the need for excess trimming or additional machining processes.

Shorter lead times, once tooling is developed, are another advantage that customers gain from the fast nature of roll forming. The rapid production cycle enables manufacturers to meet tight deadlines and deliver products within shorter time frames. This is especially beneficial for customers who require just in time delivery for their projects, allowing them to accelerate their own production schedules or respond promptly to market demands. Shorter lead times also enhance customer satisfaction by minimizing waiting periods and ensuring timely delivery of steel channels.

The speed of roll forming does not compromise the quality and precision of the final products. Advanced roll forming machines and precise tooling designs ensure consistent dimensions and tight tolerances. Roller Die can hold industry-standard tolerances and in some cases, even tighter tolerances. This level of accuracy is maintained throughout the high-speed production process, resulting in steel channels that meet the required specifications and perform optimally in various applications. We also perform quality control to ensure that pieces coming off our lines are within customer expectations and ready to go.

If you’re interested in roll forming steel channels or a wide variety of other shapes and metals, reach out to the sales team at Roller Die. Our team is experienced and knowledgeable and can help you determine if roll forming is the right fit for your project.