Category: Continuous Improvement

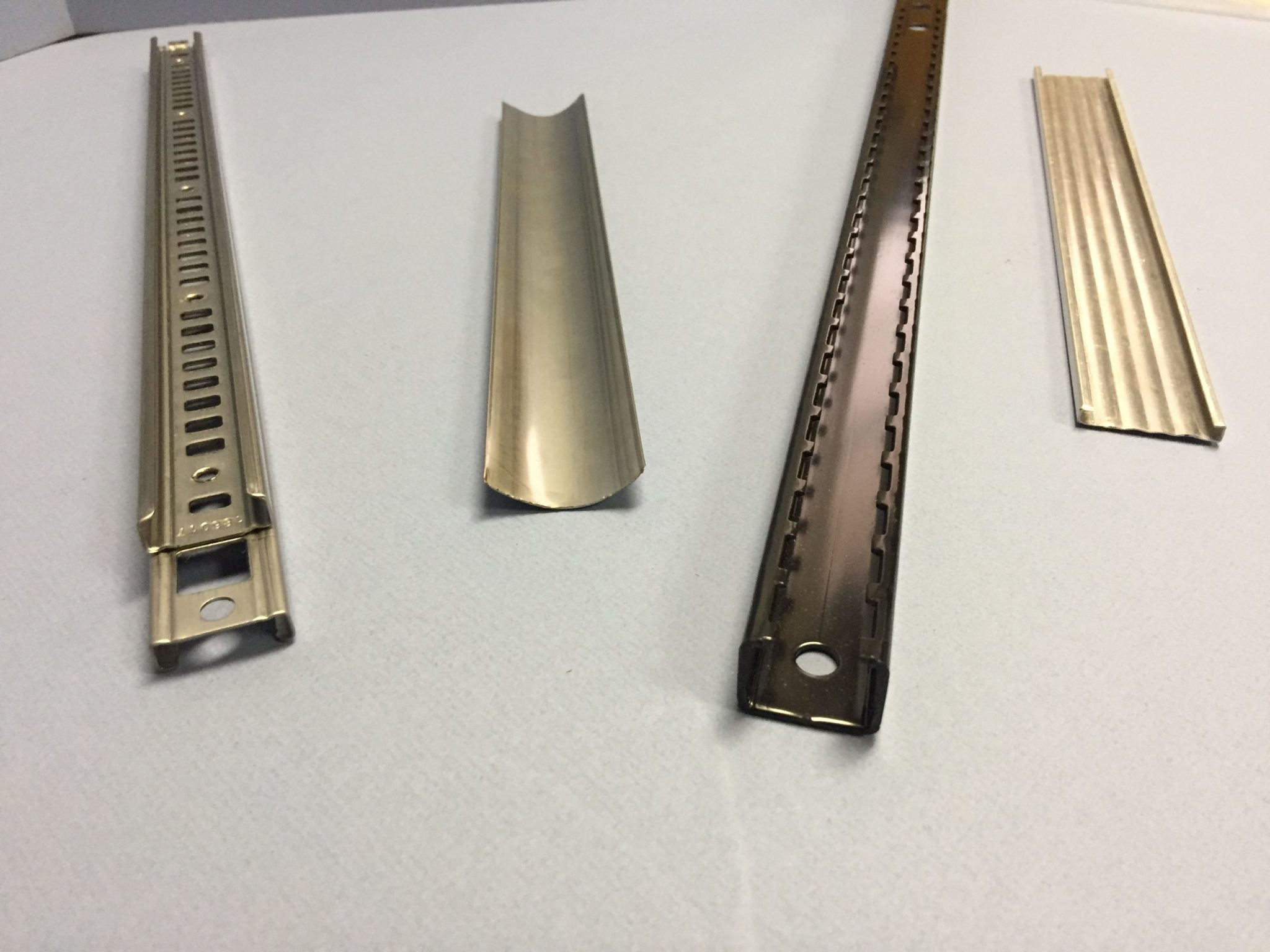

Roll Forming for the Appliance Industry

Roll forming is a highly efficient and versatile metal fabrication process that finds extensive applications in the appliance industry. Roller Die + Forming works with appliance clients to bend and

Read More

Roll Forming Makes Parts Quickly and Accurately

Roll forming is renowned for its high speed and efficiency, making it a preferred method for producing steel channels and other profiles. This speed offers several advantages to Roller Die's

Read More

The Importance of Quality

When you're considering roll form parts for your project, you're initially attracted to the cheap cost per piece and the low material waste. However, if the quality isn't present in the parts, then

Read More

How Long Does Roll Form Tooling Last?

One of the most common questions the Roller Die + Forming engineers get is how long tooling lasts, especially when a customer is purchasing custom tooling. Standard tooling is great for running many

Read More

Why Choose Custom Tooling

While we talk a lot about our Standard Tooling Library, Roller Die + Forming also makes custom tooling. For many of our customers, that's the best option and here are a few reasons why.

Customer

Read More

Optimizing Supplier Locations

When you're considering different suppliers for custom roll formed metal parts, one factor to take into consideration is the location of the supplier and related logistics of transferring parts from

Read More

Roll Forming Supports Green Jobs

We often talk about how roll forming is a lean, green, low waste, and sustainable process for creating custom metal parts. At Roller Die + Forming, many of the parts we make go on to support the

Read More

Roller Die Works with Just-in-Time Manufacturing

Just-in-time production of parts is a careful dance between suppliers and manufacturers, working to ensure the plant has the parts needed for assembly without having to warehouse the spares and

Read More

Roll Forming Prices Driven by Raw Material Pricing

As the price of steel and other raw materials continues to fluctuate and, largely, rise, the team at Roller Die is continuing to look for new ways to ensure the best possible custom metal roll

Read More

Continuous Improvement is Critical to Manufacturing Success

All companies seek to continuously improve their processes and their services, looking to create a better end product and cut waste along the way. At Roller Die, we take the process of continuous

Read More