All companies seek to continuously improve their processes and their services, looking to create a better end product and cut waste along the way. At Roller Die, we take the process of continuous improvement seriously. We are always implementing new technologies and strategies to improve our processes, our customer experience, and keep our quality top […]

Roller Die Offers Sheet Metal Press Brake as well as Roll Forming

While we often focus on the many advantages of creating parts using the roll form manufacturing process, press brake is another excellent option. Often used alongside roll forming to create parts for the automotive, appliance, and marine industries, press brakes can create custom shapes or add additional uniform bends to roll formed parts. Generally used […]

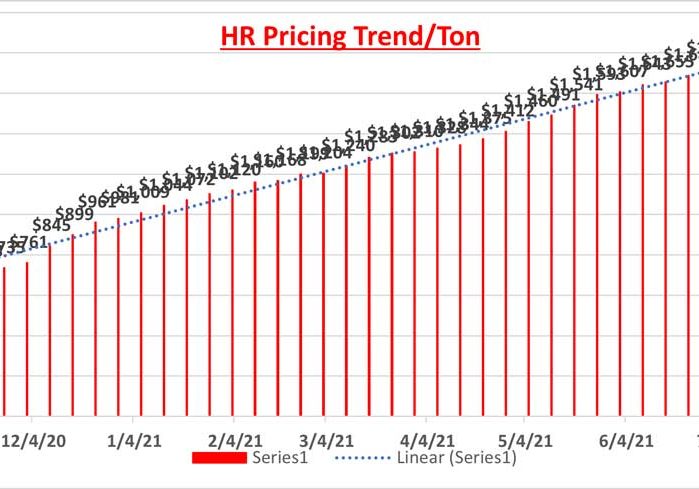

Steel Prices Continue to Rise

Following an almost perfect linear progression, steel prices over the last year have risen dramatically and continue to rise. For many of our customers, this means an increasing percentage of their piece price is now in raw materials and as consumers, we’re seeing those price increases reflected in both the cost, and supply availability, of […]

Benefits of Sourcing American Made Materials

At Roller Die + Forming, we believe that consistency and quality are requirements for our products and services. We know how important it is to be sure that our customers have access to quality products when they need them. It is equally important that we source the materials that make your products from reliable sources […]

Reusable Packaging Keeps Costs Steady

Roller Die creates parts for many industries, from solar to material handling, from conveyors to trucks. Many of our clients take advantage of manufacturing practices such as just-in-time delivery, having only the parts they need for the week or even the day show up at their plant while we adjust our output based on their […]

Roll Forming Custom Parts

When we go to trade shows or have a chance to show potential customers our samples, there are a few pieces that always get a second look. These pieces really highlight the creative extent of what you can do with roll forming. Whether it’s a complicated profile, tight tolerances on close bends, or a creative […]

Supplier Ranks Roller Die 98.4/100 During Recent Evaluation

Many Roller Die + Forming customers have evaluation programs designed to ensure their suppliers are meeting their needs in a variety of areas. Recently, a solar company Roller Die works with to provide racking conducted a supplier evaluation and gave us an A status. They ranked us on a variety of factors and we excelled […]

Roller Die Team Has Experience at All levels

From senior management down to the workers on the roll forming lines, the Roller Die + Forming team has tremendous experience in manufacturing and specifically with roll forming. That experience provides a wide range of benefits to our customers. Our sales team truly understands roll forming and can provide value from the first time they […]

The Advantages of Reusable Packaging

Many of our customers place large orders for the parts they believe they will need for the quarter, but then receive those parts weekly on a just-in-time delivery basis. This helps them keep the inventory of parts low while knowing that the parts will continue to come on time. Just-in-time delivery is also great for […]

Just-in-time Inventory Management

Having enough parts on hand to deliver each week is important, but most manufacturing companies do not want to be responsible for significant inventory. Managing and storing that inventory, transporting it from a warehouse to the plant floor, and paying attention to supply are all costs that can quickly add up. Instead, many manufacturing companies […]

Tracking the Prices of Raw Material

More and more, the price of raw materials is driving the discussion over roll formed product pricing. For the purchasing team at Roller Die + Forming, the key is knowing well in advance how much material will be required and when it is needed. That gives us time to pay attention to the market and […]

Roll Forming is a Low Waste Manufacturing Process

Waste in manufacturing is a big topic, especially when evaluating your supply chain to ensure sustainable operations. Roll forming is a surprisingly low-waste process and our team is always looking for further ways to improve our process and reduce unnecessary costs. By its nature, roll forming uses the majority of the raw material purchased, with […]